Russian scientists from the Federal Research Clinical Center of Physical-Chemical Medicine, the Moscow Institute of Physics and Technology, and Lomonosov Moscow State University have shown that it is possible to combine two incompatible components—a protein and a polymer—in one electrospun fiber.

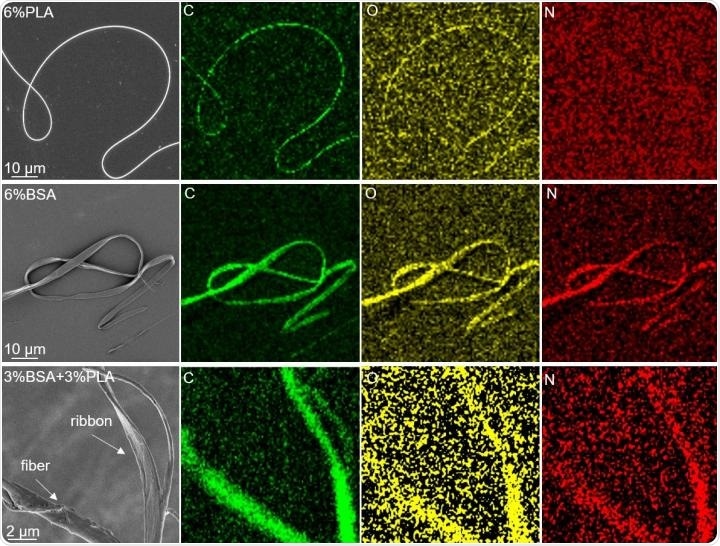

EDX analysis of the fibers made of PLA (top row), BSA (middle), and the PLA-BSA blend in equal proportions (bottom). The color mapping corresponds to the chemical elements, with the carbon, oxygen, and nitrogen shown in green, yellow, and red, respectively. The presence of nitrogen indicates the protein. Image Credit: Elizaveta Pavlova et al./RSC Advances.

The study was published in RSC Advances and illustrates that the ensuing mat can slowly release the protein. Blended mats comprising proteins are favorable for use in the field of biomedicine, as matrices for drug delivery and release, burn and wound dressings, and tissue engineering.

Electrospinning

Electrospun mats made of ultrafine fibers find several applications, such as drug delivery, liquid and gas filtering, culturing of cells, and as sorbents and catalytic matrices, in antibacterial wound dressing, tissue engineering, and protective clothing.

Electrospinning is a procedure used for developing micro- and nanofibers from polymers by applying an electrostatic field. Upon applying a higher voltage of around 20 kV, a droplet of polymer solution gets electrified, stretching into a thin fiber when the Coulomb repulsion surpasses the surface tension.

The method is quite flexible and involves integrating an array of components into electrospun mats—fluorescent dyes, micro- and nanoparticles with different properties, polymer and biopolymer mixtures, carbon nanotubes, and drugs and antibacterial agents. Thus, the properties of the mats can be adjusted to make them fit for a particular practical application.

Polymer-protein mats

In general, an electrospun mat is produced using a carrier polymer, which guarantees the stable formation of fiber, integrating additional elements. Biodegradable and biocompatible polymers are mostly preferred for biomedical applications, among which polylactic acid (PLA) is the most common one. PLA is used in the manufacture of surgical threads, degradable packaging, pins, and screws.

The major drawback of using PLA in biology and medicine is its hydrophobic nature, giving it poor cell adhesion. To overcome this drawback, the polymer is combined with proteins since they are hydrophilic, nontoxic, naturally metabolized, and can serve as therapeutic agents.

The scientists investigated blended mats made of water-insoluble PLA and a water-soluble globular protein is known as bovine serum albumin (BSA). Experiments conducted in a water medium suggest that the protein component is released gradually from the mat into the solution. Particularly, nearly half of the protein from the mat was dissolved in a week. This effect points toward the probable applications in the extended-release of protein-based drugs.

The team studied the protein distribution of the blended mats to predict their properties. The limitation is that a majority of the polymers do not coalesce well. In a polymer-protein solvent system, the constituent elements tend to separate into two solutions.

This applies to BSA and PLA solutions, but electrospinning enabled scientists to overcome the separation of phases in mats. Using three independent analytical methods—EDX spectroscopy, fluorescence microscopy, and Raman spectroscopy—they demonstrated that both components are present in every fiber.

Electrospun polymer-protein blended mats have many possible applications. By varying the amount of protein, you can tune how fast mat biodegradation happens. The protein's numerous functional groups enable us to modify the mat surface by attaching chemical compounds to it. Protein-base0d blended mats could also be used as selective filters or for prolonged drug release, for example, in burn and wound dressings.”

Dmitry Klinov, Study Co-Author and Researcher, Molecular and Translational Medicine Department, MIPT

Klinov is also the head of the Laboratory of Medical Nanotechnologies at the Federal Research Clinical Center of Physical-Chemical Medicine of the Federal Medical and Biological Agency of Russia.

Source:

Journal reference:

Pavlova, E., et al. (2020) The miscibility and spatial distribution of the components in electrospun polymer–protein mats. RSC Advances. doi.org/10.1039/C9RA10910B.