In this interview, we speak to Dr. Avinash Manjula Basavanna about his latest research that incorporated E. Coli to bring 3D printing materials to life.

Please can you introduce yourself and tell us what inspired your latest research into biomaterials?

I am Avinash Manjula Basavanna and I have been intrigued by Nature’s elegant designs and living cells’ remarkable manufacturing capabilities to produce a wide variety of materials at ambient conditions from abundantly available benign components.

My research efforts are focused on understanding and utilizing these design principles and the capabilities to develop technologies for global well-being. In this regard, I work in the emerging and exciting field of Engineered Living Materials, wherein I employ living cells as factories to make materials sustainably.

In your latest research, you designed a 3D-printable material that is alive. Can you describe how you carried out this research?

Like I mentioned above, I work on Engineered Living Materials (ELMs), which are defined as the engineered materials composed of living cells that produce the desired materials, which also inherits life-like properties such as self-regeneration, self-healing, self-regulation, environmental responsiveness, and evolvability.

In the field of ELMs, we strive to produce biological materials in a sustainable manner and to restore the circular material economy. Analogous to a seed that has all the necessary information stored within, to acquire resources from its surroundings and grow to a gigantic tree, the ultimate vision of ELMs field is to program living cells to make macroscopic materials with life-like properties. Our lab is one of the pioneers of this nascent field of ELMs.

So far, in the field of ELMs, we and other researchers have been able to program living cells to make a wide variety of materials. But, building a three-dimensional material of specific shape, size, and pattern from the engineered cells by a bottom-up approach is rather difficult, and for which one can think of utilizing a 3D printing-based top-down approach.

To 3D print, one requires a bioink that can favorably harbor the living cells and also facilitate printing into desired 3D architectures. In this regard, we decided to program the extracellular matrix of E. coli biofilm to produce the Microbial Ink.

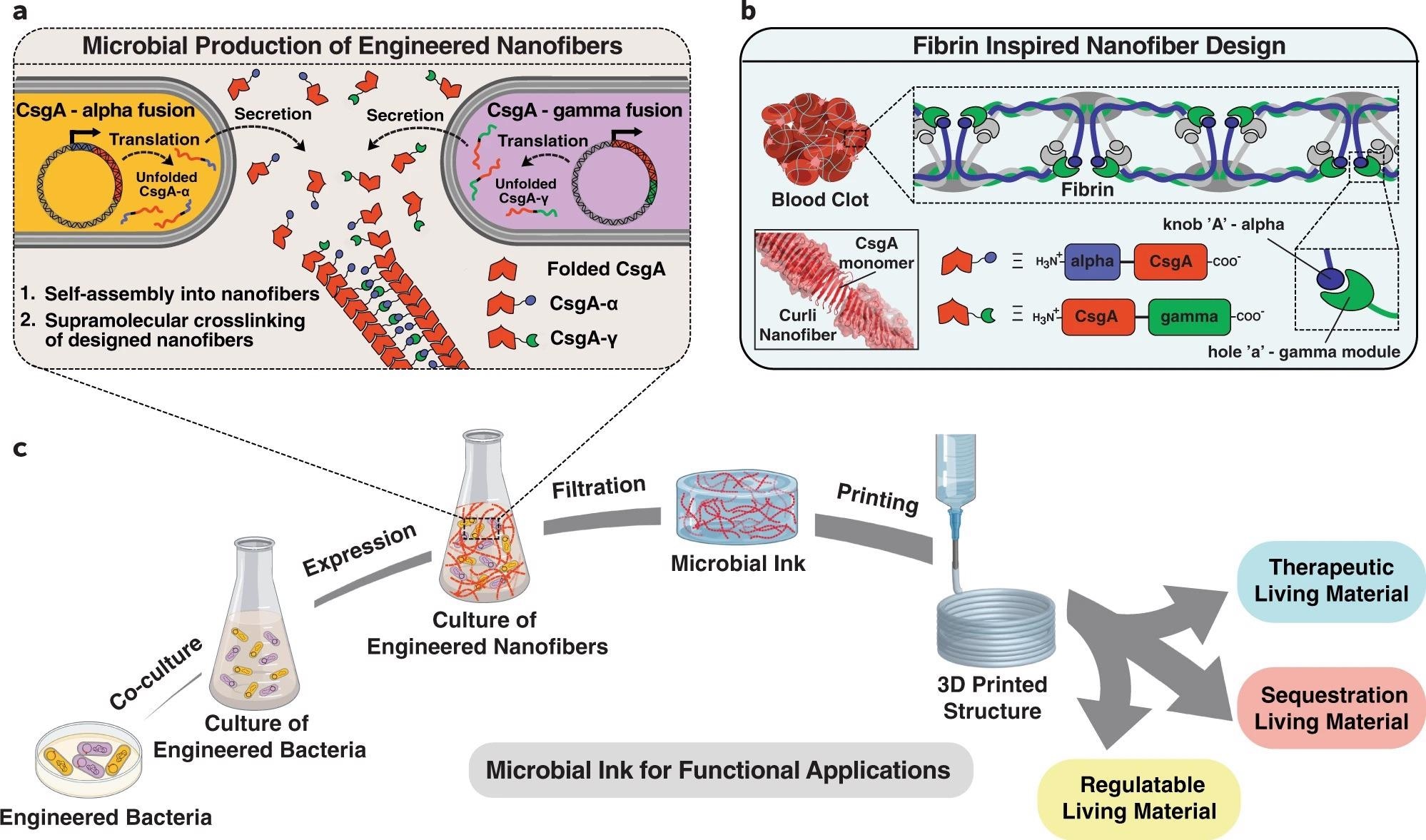

The production of a Bioink entirely from the microbes was never accomplished and it is extremely challenging, as the bioink needs to have favorable biocompatibility, stiffness, viscosity, yield strength, printability, shape, and structural integrity. To accomplish this, we introduced a genetically programmed crosslinking strategy by taking inspiration from fibrin, which is a protein involved in the formation of blood clots through the protein-protein interactions of alpha and gamma modules known as the knob-hole interactions.

With the help of detailed characterization of the Microbial Ink, we have shown that our strategy is not only effective and successful but also convenient, as it can be produced directly from the microbial culture by a simple filtration protocol, which can also be incorporated with programmed microbes for various applications.

Image Credit: Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers

Why did you choose to use E. coli to produce your biological ink compared to other bacteria? What properties does the bacterium have that are advantageous?

E. coli is one of the well-studied bacteria and to produce ELMs, we make use of a specific biofilm called curli biofilm, wherein E.coli cells are surrounded by an extracellular matrix made up of protein nanofibers called curli.

By utilizing the genetic engineering technology developed in our lab named BIND (which stands for Biofilm Integrated Nanofiber Display), we can graft any desired peptides or protein to CsgA protein, which is the building block of curli nanofibers, and thereby we can generate functional curli nanofibers and in turn functional materials. The curli nanofibers are very robust and are resistant to solvents, surfactants, pH, and denaturants, which are helpful during processing and to make robust materials.

What applications will your new biological ink have within science and medicine?

The incorporation of engineered microbes into Microbial Ink enables the fabrication of Functional Living Materials and 3D Living Architectures having predetermined shapes and patterns for biotechnological and biomedical applications. Microbial Ink could be instrumental in a better understanding of microbiomes and tissue engineering applications.

On the other hand, microbial inks could also be utilized for building structural living materials on earth or space or extraterrestrial habitats, and it is to be noted that for the latter it is difficult to transport all the raw materials from the earth.

Microbes have been used within 3D printing before. Why is your new microbial ink different from others previously made and what are the advantages of having an entirely biological gel?

Yes, there are a few examples of extrusion-based 3D printing of microbes. But in all these approaches, microbes are embedded in bioinks that are commonly utilized for printing mammalian cells in tissue engineering applications. Instead of utilizing the existing bioinks, we wanted to produce the bioink entirely from the engineered microbes.

The production of a Bioink entirely from the microbes was never accomplished and it is extremely challenging, as the bioink needs to have favorable biocompatibility, stiffness, viscosity, yield strength, printability, shape, and structural integrity. To accomplish this, we introduced a genetically programmed crosslinking strategy by taking inspiration from fibrin, which is a protein involved in the formation of blood clots through the protein-protein interactions of alpha and gamma modules known as the knob-hole interactions.

With the help of detailed characterization of the Microbial Ink, we have shown that our strategy is not only effective and successful but also convenient, as it can be produced directly from the microbial culture by a simple filtration protocol, which can then be conveniently utilized for various applications.

Image Credit: fusebulb/Shutterstock.com

You also tried mixing the ink with other genetically engineered microbes. Can you describe how you did this and what you discovered?

Microbial Ink can be customized for various applications by incorporating programmed microbes. As a proof-of-concept, we have shown that such a strategy can be utilized for developing functional living materials, namely;

- Therapeutic Living Material – to release on-demand the anticancer drug namely azurin

- Sequestration Living Material – to sequester toxic chemicals like BPA (Bisphenol A) and

- Regulatable Living Material – to regulate the growth of living cells by programming the cells to kill themselves on demand

How has 3D printing revolutionized the scientific sector and how do you see this role changing over the next 20 years?

3D printing technology has provided a unique opportunity to print three-dimensional patterns of desired shapes and sizes from different materials, which has helped researchers tremendously to better understand the structure-property correlations for applications such as fabrication of organs, implants, mechanical parts, structural components, etc.

3D printers have now become a household commodity and one can literally print anything. In the coming decades, I believe that the scientific advances in the context of speed, scale, resolution, functionality (material properties) and the new processes would enable 3D printing technology to become an integral part of manufacturing sectors, construction industry, and biomedical applications, while I am particularly excited about biomanufacturing applications.

Do you believe that your latest material could be potentially used to allow people to live on Mars? What would this mean for science if this was possible?

Well, there are several challenges for people to live on Mars, for example, oxygen, food, shelter, medication, functional materials, etc. It is unlikely that we can transport all the necessary commodities from the earth and in the long run, one has to think of ways to produce them locally by utilizing the resources available on Mars, and for which, we can think of employing microbes as living factories to produce our desired commodities.

In such scenarios, one can easily transport predesigned microbes from earth or engineer microbes as per the need on Mars, which can then be grown in bioreactors to produce our commodities in large quantities. In this direction, we believe that Microbial Ink can be incorporated with structural components like rocks present on Mars for building habitats.

Image Credit: joshimerbin/Shutterstock.com

What further testing needs to be carried before it can be commercially used?

The production of microbial ink and the examples of functional living materials reported in our work is more of a preliminary effort to showcase the different capabilities of microbial ink. In our lab, we are currently working on real applications, which might see the light sometime next year.

What are the next steps for you and your research?

Currently, my efforts are focused on constructing large-scale architectures that are mechanically robust and durable.

Where can readers find more information?

About Dr. Avinash Manjula-Basavanna

Avinash Manjula-Basavanna obtained his Ph.D. in Bioinspired Molecular and Materials Engineering at JNCASR, Bengaluru, India. He then moved to Harvard University as a Wyss Institute Postdoctoral Fellow to work on Engineered Living Materials by employing Microbes as factories to produce Sustainable Materials with Integrated Life-like Properties. Recently, he has moved to Northeastern University along with his PI from Harvard and also works at the Massachusetts Institute of Technology (MIT) as a Research Affiliate. His research interests are at the interface of Synthetic Biology, Bioinspired Materials Engineering, Nanotechnology, Microbial Factories, Protein Engineering, Biomanufacturing, 3D Printing, and Sustainability.

In 2020, he was featured as one of the World’s Top 35 Innovators Under 35 by Technology Review, MIT. He was the Grand Prize Winner of the American National Science Foundation (NSF) Idea Machine (Big Idea) competition and was also recognized with Deep Tech Pioneer and Gandhian Young Technological Innovation Awards. He was also selected for the Innovation Scholars In-Residence Program by the President of India and Harvard Innovation Lab’s Venture Incubation Program.