In recent years, the use of online process analytical technology (PAT) in the biotechnology industry has become a preeminent endeavor.

Since the start of the 1980s, numerous fermentation scientists have utilized the reliability of Thermo Scientific™ Process Mass Spectrometers to monitor the composition of gas streams into and out of fermenters and bioreactors.

When taking the first steps towards process control, it is not atypical for some to think that the only effluent required is the measurement of carbon dioxide and oxygen and that enough accuracy can be achieved by discrete measurement technology. It would be wrong to make assumptions.

Due to external biological factors – trees and people – that inevitably change the input to the instrument air system, the variability of sparge gas remains consistent. The all-pervasive twin-tower desiccant dryer systems will also either regurgitate or absorb CO2 depending on their position in the regeneration cycle.

To facilitate an accurate pre-screening for potential contamination, only a precise comparison of effluent and sparge gas is appropriate. What is more, an accurate comparison is also necessary to calculate information in real-time regarding culture respiration and the availability of nutrients.

For suitable control, the minimum requirements are as follows:

- All gas components must be measured

- Automatic calibration of all components

- Flexible analysis schedules and techniques

- High accuracy is needed to calculate meaningful metrics

- Local support

- Measurement of sparge and effluent gases

- Operational reliability and simplicity

Figure 1. Typical benchtop bioreactor. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Magnetic Sector

Analytical Performance |

N2 |

N2 |

O2 |

O2 |

Ar |

Ar |

C2 |

C2 |

| %mol |

%mol |

%mol |

%mol |

%mol |

%mol |

ppm |

ppm |

| Mean |

St Dev |

Mean |

St Dev |

Mean |

St Dev |

Mean |

St Dev |

| Day 1 |

78.0807 |

0.0028 |

20.9459 |

0.0026 |

0.9337 |

0.0003 |

396.84 |

1.31 |

| Day 2 |

78.0767 |

0.0023 |

20.9494 |

0.0023 |

0.9342 |

0.0003 |

397.46 |

1.25 |

| Day 3 |

78.0761 |

0.0024 |

20.9500 |

0.0023 |

0.9342 |

0.0003 |

397.34 |

1.28 |

| Day 4 |

78.0798 |

0.0023 |

20.9469 |

0.0023 |

0.9337 |

0.0003 |

396.31 |

1.31 |

| Day 5 |

78.0777 |

0.0030 |

20.9487 |

0.0028 |

0.9339 |

0.0003 |

396.76 |

1.34 |

| Day 6 |

78.0741 |

0.0023 |

20.9518 |

0.0022 |

0.9344 |

0.0003 |

397.47 |

1.27 |

| Day 7 |

78.0750 |

0.0023 |

20.9512 |

0.0022 |

0.9342 |

0.0003 |

397.23 |

1.30 |

Taking the first steps towards advanced process control

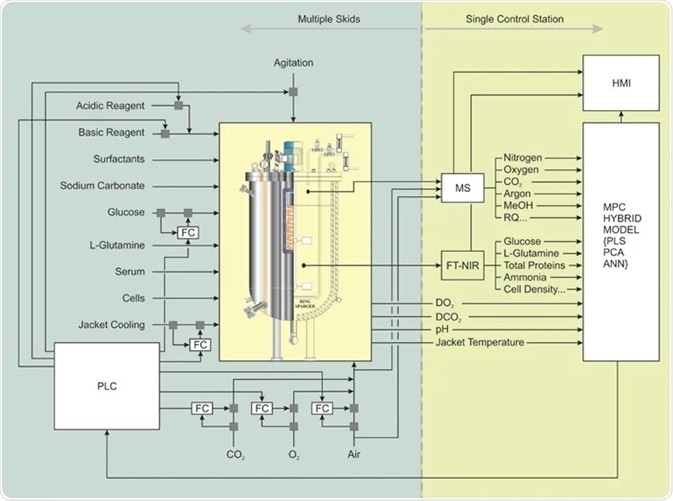

A fully instrumented fermenter is exhibited in the process diagram. In order to track a wide range of process variables in real-time, both liquid and gas-phase measurements are provided.

These data are input into the advanced process control (APC) system, which typically includes hybrid models comprised of neural (nonlinear) network models and formal (linear) models.

The APC system provides the set-points for numerous variables, which include sparge content and flow, control of nutrients and amino acids, in addition to the conventional variables of temperature, pressure, agitation and pH.

This diagram demonstrates the optimal situation for process scale-up and understanding, but there is a detailed amount of complexity and expense associated with this expansive technique.

The more common technique is to add a multi-stream mass spectrometer due to it offering a considerable amount of extra value with minimum risk and moderate cost. The Thermo Scientific™ Prima PRO has the capacity to monitor 60+ fermenters without compromising sterility.

For smaller-scale fermenters that are configured with 15 samples and six calibration ports, the Prima BT is a good bench-top solution. The complete gas composition measurements supplied by both models are both accurate and easily incorporated into the APC system.

Great improvements in process control can be rapidly achieved rapidly within one or two days of a start-up.

Figure 2. Fully instrumented fermentor. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Supplying value during every stage of product development

Advanced instrumentation is necessary for the complicated manufacturing processes which are intrinsic to biotechnology in order to optimize the clear path to the final product. Mitigating risk throughout the scale-up process is the key to increasing profits.

The Prima PRO and Prima BT process mass spectrometers offer the speed and accuracy required to monitor process dynamics reliably and facilitate timely corrective action.

The Prima platform technology helps bring products to market more quickly, enhance yields and increase profits - and offers a fast return on investment, from research and development to the final product.

Acknowledgments

Produced from materials originally authored by Thermo Fisher Scientific

About Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

We design and manufacture industry-leading products for Gas & particulate pollutants, Flow, gas and liquid measurement, Process analytical measurements, and Industrial Hygiene.

We design and manufacture industry-leading products for Gas & particulate pollutants, Flow, gas and liquid measurement, Process analytical measurements, and Industrial Hygiene.

Technologies have proven to help customers improve efficiency, ensure process and quality control, maintain regulatory compliance, and increase worker safety.

Process mass spectrometers

Maximize product yield and increase profitability with process mass spectrometry analysis. Process gas analyzers are engineered to meet a number of challenging process applications in the petrochemical, iron, and steel, and biotechnology industries. Highly reliable and easy-to-own, Thermo Fisher Scientific process gas analysis technologies deliver faster, more complete, lab-quality online gas analysis and process analytics. Learn More

Process Analytical Technology/Biopharma

Process Analytical Technology (PAT) is a regulatory framework initiated by the United States’ Food and Drug Administration (FDA) that encourages pharmaceutical manufacturers to improve the process of pharmaceutical development, manufacturing, and quality control.

PAT aims to improve process efficiency by defining Critical Process Parameters (CPP) and monitoring these CPPs to stay within a defined limit, either in-line or on-line to maintain a product’s Critical Quality Attributes (CQA). Monitoring CPPs with process mass spectrometry gas analysis reduces over-processing, pinpoints contaminants, and increase product consistency. Learn More

Industrial hygiene

Industrial hygiene instruments keep your investments secure, your facilities compliant with local regulations, and your workers safe from leaking pollutants, gases, or toxic vapors. Make sure you have the most updated technology, with access to repair and calibration support to maintain reliable gas monitoring. With our environmental expertise, you can breathe easy knowing your company, workers, and neighboring communities have cleaner, safer, and healthier air quality. Learn More

Sulfur analyzers

Online sulfur analyzers replace expensive and time-consuming laboratory sampling. Get fast responses and wide measurement ranges of trace sulfur and total sulfur in flare gas, liquid, and vapor for reliable emissions monitoring. Learn More

Gas & particulate analyzers

Increasingly stringent regulatory requirements are making it more difficult to maintain regulatory compliance and optimal process performance. Air quality monitoring and reporting requirements in the U.S., China, India, Europe, and Latin America are shifting and being redefined. Together we can arrive at solutions that make sound business sense. Learn More

Flow measurement

Flow measurement and process control are critical aspects of producing, handling, and transporting hydrocarbons around the world. With our Thermo Scientific suite of flow computers and flow meters, we enable our customers to reduce cost, decrease lost material, automate, and monitor critical points in processes. From field to control room and upstream to downstream, our products provide greater control, confidence, and reliability. Learn More

Sponsored Content Policy: AZO Life Science publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of AZO Life Science, which is to educate and inform site visitors interested in medical research, science, medical devices, and treatments.