Overview

The first Two-Photon Grayscale Lithography (2GL®) system in the world brings together the exceptional performance of grayscale lithography with the accuracy and adaptability of Nanoscribe’s ground-breaking Two-Photon Polymerization (2PP) technology.

For industrial production of 2.5D freeform microoptics, microlens arrays, and multi-level diffractive optical elements, the maskless lithography system known as Quantum X is the best option.

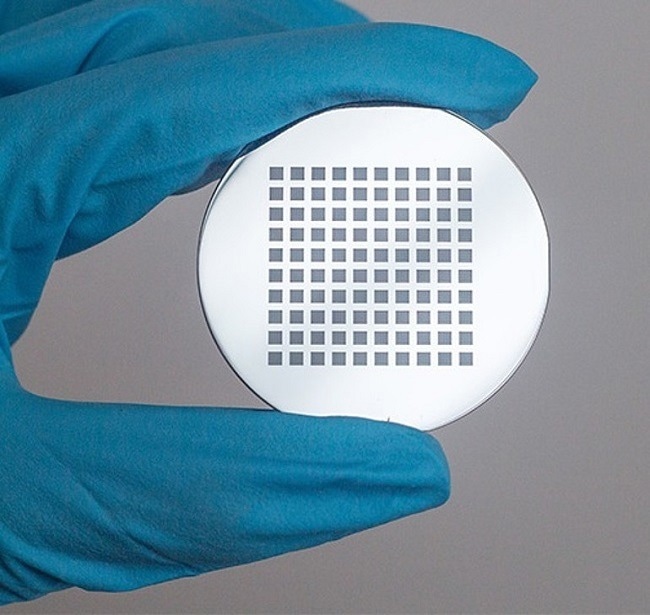

Image Credit: Nanoscribe

Quantum X uses synchronized laser power modulation at high speeds to regulate the voxel size along a scanning plane. Complex shapes can be created this way, and different feature heights can be achieved within a single scan field.

Two-Photon Grayscale Lithography (2GL) enables printing of discrete and accurate steps as well as essentially continuous topographies on substrates up to six inches in diameter without additional lithography steps or mask fabrication.

Microfabrication and other industrial manufacturing tasks are made possible by the significant design freedom provided by 2GL’s additive manufacturing technology.

In industrial manufacturing and replication processes, Quantum X is made for quick prototyping and mastery. The fabrication of freeform microoptics, microlens arrays, and multi-level diffractive optical elements is redefined by this maskless lithography system’s performance in two-photon grayscale lithography.

Utilize the touchscreen on the device to manage the print job. Through nanoConnectX, users can monitor their Two-Photon Grayscale Lithography system from the office and in multi-user or multi-system configurations. Users can also benefit from wafer-scale batch production that is time-efficient and adheres to industry standards for superior industrial manufacturing.

Features

- Industrial platform for wafer-scale fabrication and small series production

- Touchscreen and remote-control interfaces for a straightforward and consistent workflow

- Additive manufacturing by Two-Photon Grayscale Lithography with highest precision and submicron shape accuracy

- Complete and ultrafast single voxel size control for optical-grade, smooth surfaces

- High-performance microfabrication with proprietary galvo scanning technology

- High-speed industrial manufacturing of 2.5D topographies with complete design freedom and sub-micron resolution

- Ultra-fast voxel modulation rate and 100 nm address grid for optical-grade smooth surfaces

- Interface finder for transparent, opaque, and reflective surfaces with nanometer precision

- Automated self-calibration routines for most accurate laser power control and positioning

- Broad range of substrates and wafers up to 6”

- Touchscreen and remote control ensure an easy workflow

- Continuous execution of various print jobs by job queue

- 2.5D grayscale lithography 2GL

- Single voxel tuning with 2GL® for high-performance additive manufacturing of 2.5D topographies

- Wafer-scale batch processing

- A fully addressable 25 cm2 print field on wafers up to 6” in small series production

- Industrial manufacturing

- Automatic calibration routines and user-friendly software for submicron shape accuracy

Application areas

- Two-Photon Grayscale Lithography (2GL®) for stunningly rapid and accurate surface patterning

- Single and multi-layer support with 4,000 gray levels each

- Nanoscale printing-feature size control in all spatial directions down to 100 nm

- Microscale printing-with typical dimensions from 50 to 700 μm

- Mesoscale printing-with dimensions up to 25 cm²

- Refractive microoptics-individual lenses and arrays

- Multi-level diffractive optical elements—up to 256 discrete or quasi-continuous levels

- Rapid prototyping of 2.5D microoptics by direct laser writing lithography

- Rapid tooling with patterned polymer masters for replication processes

- Small series production

- Wafer-scale batch production

Specifications

Benchmark scores

Table 1. Source: Nanoscribe

| . |

. |

| Surface roughness (Ra) |

down to ≤ 5 nm |

| Feature size control 1 |

down to 100 nm |

| Shape accuracy |

down to ≤ 200 nm |

| Autofocus precision |

down to ≤ 30 nm |

| Print field diameter |

25 mm divided by lens magnification |

| Maximum scan speed 2 |

6.25 m/s divided by lens magnification |

General system properties

Table 2. Source: Nanoscribe

| . |

. |

| Printing technology |

Two-Photon Grayscale Lithography (2GL®) with voxel tuning capability |

| Substrates |

Microscope slides (3 x 1” / 76 x 26 mm)

Wafers from 1” to 6” (25.4 mm to 150 mm)

Glass, silicon, and further transparent and opaque materials |

| Photoresins |

Nanoscribe IP Photoresins (polymer printing)

Nanoscribe GP-Silica (glass printing)

Open for third-party and custom materials |

| Maximum print area |

50 x 50 mm² |

Given values may vary depending on the photoresin and structure geometry.

1 100 nm feature size control in all spatial directions

2 e.g. for 10x magnification: 625 mm/s

My first print job worked flawlessly and the structure is stunningly good, if not to say sensational. I have never seen anything like this before.”

Dr Harald Giessen, Professor, University of Stuttgart

How to get started with the print job?

Prepare and control the print job via touchscreen or remotely

Video Credit: Nanoscribe

- It is simple and convenient to integrate Quantum X into multi-user scenarios and industrial manufacturing environments

- Directly from the touchscreen of the device or remotely from the computer, users can upload, print, and monitor their print job

- Generate the print job with GrayScribeX

- The print job development software takes users through each step of the process, from project creation to uploading their unique project as a proprietary .nano file to the maskless lithography system Quantum X

- Start the print job via the touchscreen

- Quantum X’s user-friendly touchscreen menu leads users to successful printing with ease. Profit from crucial information like hardware details, system status, and print progress

- Users can always control the print process visually, thanks to a live view provided by three cameras

- Stay connected with nanoConnectX

- The remote access software nanoConnectX allows users to start and monitor the print job from the office

- Quantum X system is prepared for multi-user environments and industrial manufacturing settings

Software facts

GrayScribeX

- For Quantum X, a specially designed piece of software called GrayScribeX is used to create customized print jobs

- Users can import CAD models that have been automatically converted into grayscale images or common grayscale images

- A clever software routine precisely sets the calibrated print parameters by converting the grey values from the imported design into the heights of the print object

Table 3. Source: Nanoscribe

| Key feature |

Benefits |

| Import of 16 bit grayscale images and CAD files |

Use standard image files .bmp and .png as well as the CAD format .stl |

| Remote upload of print jobs |

Work and connect remotely with Quantum X from the office |

| Add, remove and duplicate structures to the print job |

Create print jobs of different structures in one file |

| Rescale your structures and create arrays |

Modify the structures to meet individual requirements for the corresponding application |

| Field-proven print parameter presets |

Benefit from ready-to-use preset parameters for straightforward printing of any grayscale design |

| Internal calibration files |

Easily translate your gray values into the corresponding writing parameter |

| .nano files |

Take advantage of the container file format that includes all necessary information for data exchange and a successful print in a single file |

Touchscreen

- Utilize the graphical user interface (GUI) on the Quantum X front panel touch screen to control and monitor the Two-Photon Grayscale Lithography system

- It leads users through the necessary steps for a successful print. After choosing the print project, load the substrate, and finally print

Table 4. Source: Nanoscribe

| Key feature |

Benefits |

| Three live cameras |

Monitor the printing process online from three perspectives and always be up to date on the current status of your print job |

| Stage control in x, y and z direction |

Move the stage to any position on the substrate to define your print area |

| User-friendly print setup |

Select resin and substrate, and start the print job with just one click |

| Project list |

Keep track of the entire print job history |

| Automatic interface finder |

Identify the interface of the substrate with submicrometer accuracy |

nanoConnectX

- Quantum X’s remote access software is called nanoConnectX. Any computer that is connected to the internet now has access to all the touchscreen's features and display capabilities

Table 5. Source: Nanoscribe

| Key feature |

Benefits |

| Remote access to the system |

Connect Quantum X to your computer, no matter where you are |

| Use all features of the touchscreen |

Prepare, control and monitor your print jobs from any location |

| Upload and download print jobs and reports |

Direct access from your computer towards print related files |