Overview

A bioprinter with the highest resolution, the Quantum X bio is incredibly versatile and capable. The proprietary technology is tailored and reimagined through the eyes of a biologist and powered by Two-Photon Polymerization (2PP) and grounded in engineering excellence.

The 3D bioprinter with direct laser writing technology provides crucial features like precise temperature control, sterile surroundings, and functionalized biomaterials that open up a new level of bioprinting and significantly speed up innovation in vital fields like tissue engineering, cell biology, and the full spectrum of biomedical applications.

Thus, the power of bio convergence is represented by Quantum X bio.

Video Credit: Nanoscribe

With unmatched accuracy and speed, print virtually any 3D design, accelerate design iterations to maximize research, and take advantage of a variety of biomaterials, bioinks, and biocompatible resins.

By tapping on a touch screen, even filigree and complex 3D structures can be placed intuitively and with the highest degree of precision into microfluidic channels or wells.

In light of this, Quantum X bio is the best two-photon lithography tool for developing sophisticated microenvironments for tissue engineering, unique scaffolds for cell studies, and numerous other cutting-edge biomedical applications where accuracy, speed, material diversity, and sterility are crucial.

Users of Quantum X bio gain access to UX-optimized software from Nanoscribe, as well as a bioprinting library with tested STL models. It might be simple to print successfully if the sensor and video data monitoring is combined with printing.

The two-photon polymerization print job can be uploaded, started, and monitored remotely from the PC or directly from the touchscreen of the device.

Users are in a prime position to investigate the full spectrum of biological and biomedical applications with Quantum X bio. Benefit from sterile accessories, biomaterials, and bioinks, in addition to a sterile, temperature-controlled substrate holder.

There are also numerous custom materials supported. Users are fully equipped to investigate live cell printing with Quantum X bio.

Features

- Rapid prototyping with highest precision and design freedom along a straightforward workflow

- Filtered airflow ensures sterility

- Temperature-controlled substrate holder

- Wide range of universal and application-specific printing materials available for high-resolution 3D printing, including sterile biomaterials and bioinks

- Bioprinting STL library

- 3D bioprinter based on two-photon polymerization with cell-friendly wavelength 780 nm

- Industry-proven two-photon lithography platform for many substrates types

- Ready for exploring live cell printing using custom bioinks

- Sterile printing conditions provided by filtered airflow, sterile consumables, and autoclavable parts

- Open direct laser writing platform allows the use of custom materials

- Printing into cell culture dishes or onto microscope slides for workflow compatibility

- Touchscreen and remote control ensure high usability

- High-speed 3D Microfabrication with ultra-fast voxel modulation rate

- Sensor and video data collection during print

- Quick start and inspiration by bioprinting STL library

- Ideal for multi-user facilities: Modular system for wide range of applications

- Next level of bioprinting

- Start using high-performance 3D bioprinting with submicron features on surfaces as small as 25 cm2

- Wide choice of substrates

- Take sterile microscope slides and cell culture dishes that are appropriate for the lab’s workflow

- Biomaterials and bioinks

- Select from biocompatible printing media, biomaterials, and bioinks. Custom materials are also an option

Application areas

- 2PP-based 3D bioprinting (direct laser writing)

- 2GL Two-Photon Grayscale Lithography available for stunningly rapid and accurate surface patterning

- Nanoscale printing-subcellular feature size control in all spatial directions down to 100 nanometers

- Microscale printing-with typical object dimensions from 50 to 700 micrometers

- Mesoscale printing-with dimensions up to 50 millimeters

- Cell scaffolds

- Skin/tissue models

- Smart/living materials

- Microfluidics

- Microneedle arrays

- Drug delivery vectors

- Micro/soft robotics

- Vascular models

- Topology for cell mechanics and migration

- Biosensors

- Sub-micron patterning

Services

Be ready for live cell printing

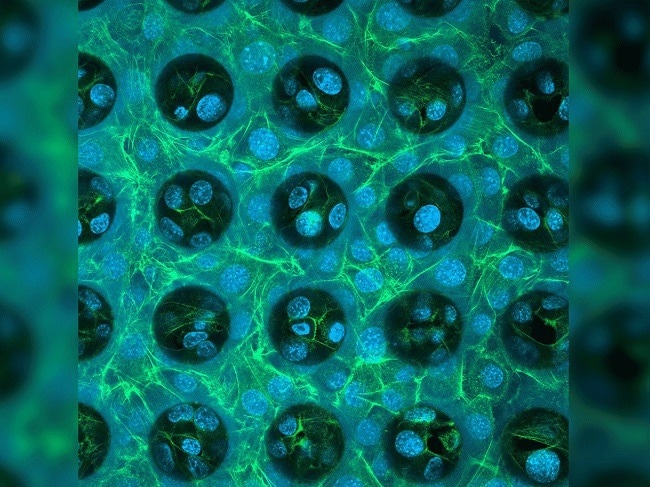

3D structure containing living NIH 3T3 fibroblast cells, printed from a cell-laden Gelatin methacrylate (GelMA) bioresin. Cell viability one hour after printing is > 90% as obtained by live-dead staining. The animation consists of different focus layers above and mainly within the printed structure. Image Credit: Nanoscribe

- The Quantum X bio two-photon lithography system has all the features necessary to print with bioresins that contain living cells and maintain their viability. This enables users to investigate fascinating new uses for smart or living materials, 3D tissues models, and other materials

- Sterile, temperature-controlled environment

- Use custom bioresins based on hydrogels

- Cell-friendly wavelength (780 nm)

- Cell viability >90 % possible

New benchmarks for 3D bioprinting

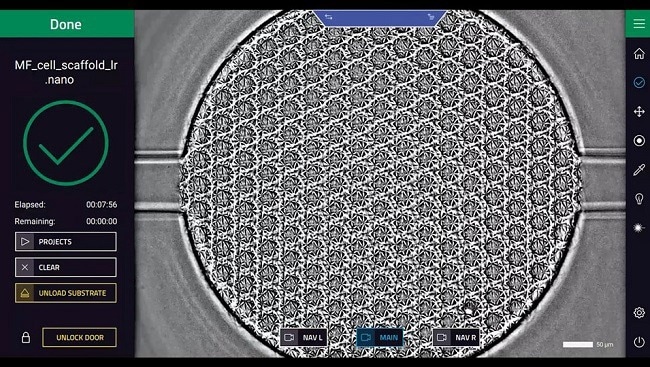

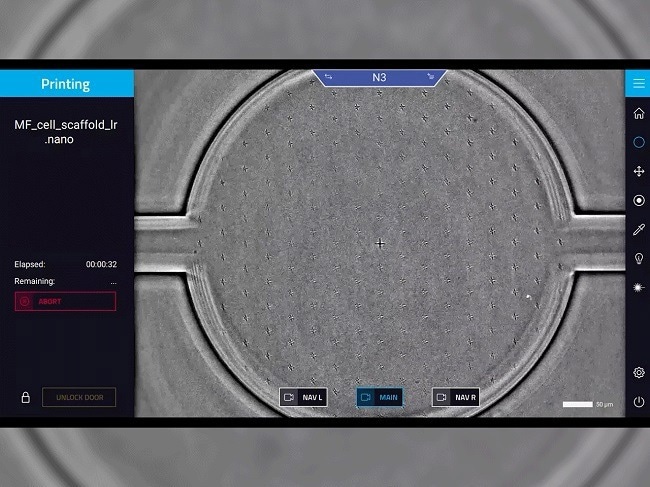

3D printing of microwell arrays for the cell culturing (first: Quantum X bio system camera image). The fluorescent NIH 3T3 cells are attached to the biocompatible scaffold made of IP-S whereby they proliferate (second: fluorescence microscope image). Image Credit: Nanoscribe

Microfabricate complex vascular models across multiple scales to mimic in vitro environments and phenomena. Herein this image, a simple vascular model is shown with dyed water. Image Credit: Nanoscribe

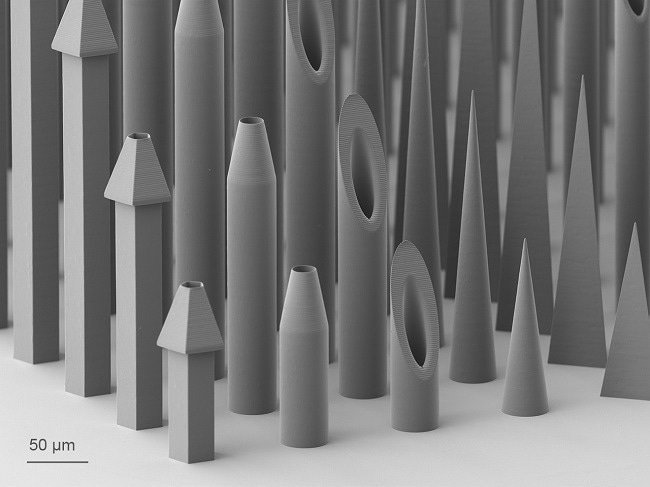

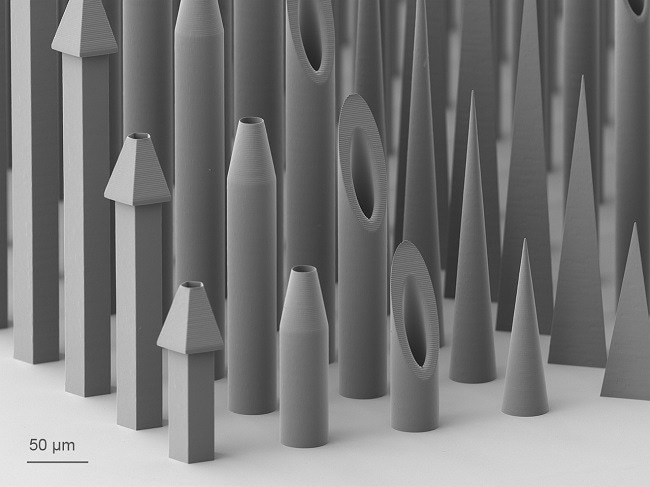

The 3D-printed microneedles in this image represent many possible biomedical applications as microfluidic devices, drug delivery vectors, microrobots, biosensors, and sub-micron patterning. Image Credit: Nanoscribe

Specifications

Benchmark scores

Table 1. Source: Nanoscribe

| . |

. |

| Feature size control 1 |

down to 100 nm |

| Shape accuracy |

down to ≤ 200 nm |

| Single print field diameter |

up to ≥ 4,000 µm |

| Maximum scan speed 2 |

6.25 m/s divided by lens magnification |

| Cell viability in live-cell printing 3 |

> 90 % (1 h after printing)

> 85 % (4 h after printing) |

General system properties

Table 2. Source: Nanoscribe

| . |

. |

| Feature size control 1 |

down to 100 nm |

| Printing technology |

Layer-by-layer 3D printing based on Two-Photon Polymerization (2PP)

Two-Photon Grayscale Lithography (2GL®) with voxel tuning capability |

| Substrates |

Microscope slides (3 x 1” / 76 x 26 mm)

MatTek cell dishes (35 mm or 50 mm)

Wafers from 1” to 6” (25.4 mm to 150 mm)

Glass, silicon, and further transparent and opaque materials

other substrates/sizes on request |

| Photoresins |

Hydrogels from Advanced BioMatrix

Bioinks from BIO INX

Nanoscribe IP Photoresins (polymers)

Nanoscribe GP resins (glass)

Open for third-party and custom materials |

| Maximum print area |

50 x 50 mm² |

Given values may vary depending on the photoresin and structure geometry.

1 100 nm feature size control in all spatial directions

2 e.g. for 10x magnification: 625 mm/s

3 Cell viability demonstrated in several of our own experiments based on live-dead counting

Organize the Quantum X bio print jobs with software and data support

Field-proven 3D bioprinting software for Life Science applications

Image Credit: Nanoscribe

- How can the final 3D printed structure be obtained from the 3D design? Users can easily achieve their successful print by using Nanoscribe’s software solutions. Create, upload, print, and keep an eye on the print job directly from the touchscreen of the device or remotely from a PC

- Generate the 3D print job with DeScribeX

- The 3D print job development software walks users through the process of importing 3D CAD models and uploading print jobs in just a few simple steps. It is based on the field-tested 2PP software DeScribe

- Get inspired by the CELLINK STL bioprinting library

- Take advantage of a large collection of tested STL models that users can download and modify for their needs. This makes printing successfully incredibly simple

- Start the print job via the touchscreen

- The Quantum X bio’s user-friendly touchscreen menu leads users to successful printing with ease. Profit from important information like hardware details, system status, and print progress

- Users can also control the print process visually at any time, thanks to a live view provided by three cameras

- Stay connected with nanoConnectX

- NanoConnectX, a remote access software, allows users to start and monitor the print job from their office. Therefore, production settings and multi-user scenarios are well suited for the Quantum X bio

Software facts

DeScribeX

- Individual 3D prints can be made using the print job development software DeScribeX. STL files, a popular 3D CAD format, can be loaded using the integrated import wizard

- The pre-installed software printing parameter presets are excellent starting points that lead users to a successful print in a short amount of time. Remote print job transfer to the Quantum X bio is made simple by the export function

Table 3. Source: Nanoscribe

| Key feature |

Benefits |

| 3D CAD model import wizard |

Intuitive workflow generates suitable print job files from standard STL files |

| Print parameter presets |

Ready-to-use preset parameters to achieve optimal printing results right out of the box |

| Adaptive slicing |

For surface refinement and improved shape accuracy |

| Parameter sweep |

For easily finding perfectly matching print parameters for new materials and applications |

| Integrated Development Environment (IDE) |

Experts can generate and modify print files (GWL) for customized and sophisticated printing tasks |

| 3D preview and printing simulation |

What you see is what you print! DeScribeX displays parameters such as print time, scan speed or laser power and simulates the whole printing process in detail |

| .nano files |

Take advantage of the container file format that includes all necessary information for data exchange and a successful print in a single file |

STL bioprinting library

- Take advantage of the extensive STL model library that CELLINK and Nanoscribe have provided together. Choose a design from our database, download it, and then modify it to fit the user’s needs rather than spending hours creating designs in CAD

- The designs offered are based on actual applications developed by our customers. Users can use the designs on other bioprinters, such as CELLINK’s Lumen X+, in addition to the Quantum X bio because the designs are scalable. This is the quick route to printing success

Touchscreen

- Utilize the graphical user interface on the Quantum X bio front panel touch screen to control and monitor the system (GUI). It leads users through the necessary steps for a successful print. Then load the substrate and begin printing after choosing the print project

Table 4. Source: Nanoscribe

| Key feature |

Benefits |

| Three live cameras |

Monitor the printing process online from three perspectives and always be up to date on the current status of your print job |

| Stage control in x, y and z direction |

Move the stage to any position on the substrate to define your print area |

| User-friendly print setup |

Select resin and substrate, and start the print job with just one click |

| Project list |

Keep track of the entire print job history |

| Automatic interface finder |

Identify the interface of the substrate with submicrometer accuracy |

nanoConnectX

- Quantum X systems use nanoConnectX as their remote access software. Any computer that is connected to the internet now has access to all the touchscreen's features and display capabilities

Table 5. Source: Nanoscribe

| Key feature |

Benefits |

| Remote access to the system |

Connect Quantum X bio to your computer, no matter where you are |

| Use all features of the touchscreen |

Prepare, control and monitor your print jobs from any location |

| Upload and download print jobs and reports |

Take advantage of a direct access from your computer to print-related files |

Print into cell culture dishes or onto microscope slides for workflow compatibility. Profit from sterile consumables and autoclavable parts. Use functionalized biomaterials and bioinks. Be ready to explore live cell printing. Image Credit: Nanoscribe

The 3D-printed microneedles in this image demonstrate the capabilities of Nanoscribe’s microfabrication technology to realize high aspect ratio, hollow and sharp tip applications with unmatched precision. Various biocompatible material options are available. Image Credit: Nanoscribe

Create your own custom microfluidics with integrated structures to mimic in vivo microenvironments. Alignment is easily done by a tap on the touch screen. Image Credit: Nanoscribe