Overview

The breakthrough cell culture technology from CYTENA will help users expedite their cell line development procedure.

Companies are striving for competitive advantages in cell line development as the biopharmaceutical business grows. The S.NEST, a high-throughput microbioreactor with CO2 incubator capabilities, lessens the time taken for cell upscaling, gives a superior microscale environment for cell growth, and improves cell line selection efficiency.

S.NEST™—How it works?

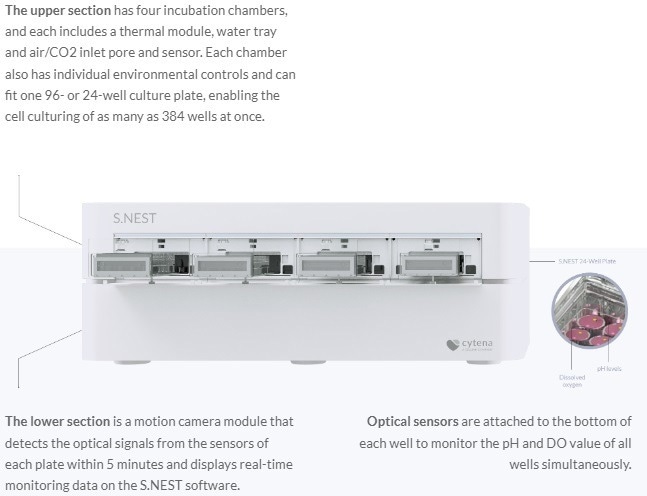

- Culture: A high-throughput cultivation method that allows for the simultaneous incubation of four 24-well or 96-well plates.

- Optimize: Mixing levels can be customized thanks to a distinctive fluid control mechanism that promotes cell growth.

- Improve: Inventive parts and intelligent design that reduces evaporation’s impact.

- Monitor: Continuous monitoring of pH and dissolved oxygen (DO) levels throughout the cell culture timeline.

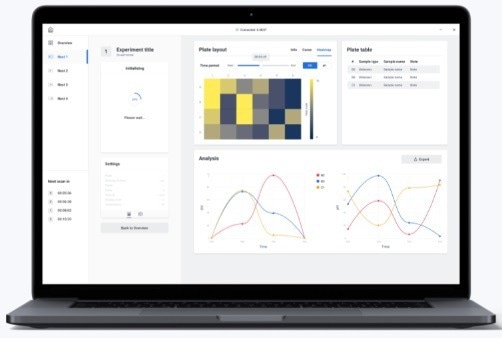

- Analyze: Intuitive software analysis that converts data into knowledge.

- Trust: Credible findings that allow the user to optimize their cell culture operations.

Features

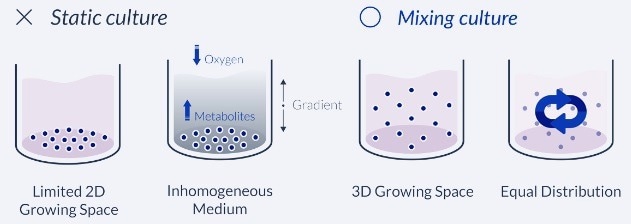

Maximum productivity with minimum effort

The S.NEST adds suspension culture and late-stage bioreactor conditions to the early-stage cell line creation pipeline, allowing for more growth area and oxygen than static cultures. When employing the S.NEST, cells have higher density and survivability than when incubated normally, and weeks of cell expansion are no longer required.

Image Credit: CYTENA GmbH

Image Credit: CYTENA GmbH

Image Credit: CYTENA GmbH

Real-time monitoring

The S.NEST software presents sensor information and enables users to modify environmental settings.

Image Credit: CYTENA GmbH

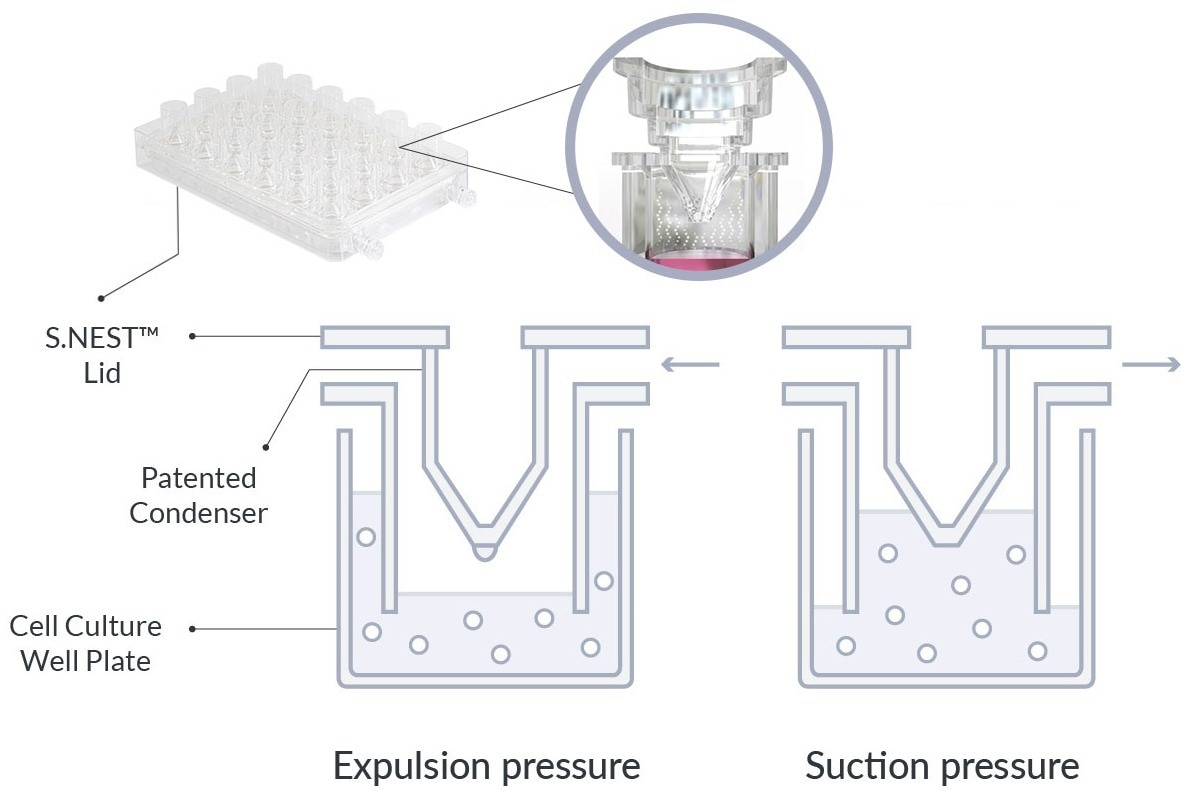

Consumables for optimal cell culture

The S.NEST lid is available with 96 or 24 fluidic channels, which cover the respective well plates. The fluidic channels’ innovative condenser design efficiently lowers liquid evaporation. Every mixing, the condensation accumulated on the surface of the condenser circulates back to the culture.

Image Credit: CYTENA GmbH

Increased oxygen transfer

To enable homogeneous reciprocating mixing, the S.NEST applies suction or expulsion pressure through the fluidic channels. Customizable mixing control reduces the shear rate for various cell lines.

The oxygen transfer tubes connected to the lid provide constant oxygen flow to the cells, ensuring a healthy environment.

Image Credit: CYTENA GmbH

Applications

- Cell line development

- High-throughput suspension culture

- Cell culture upscaling

Featured workflow

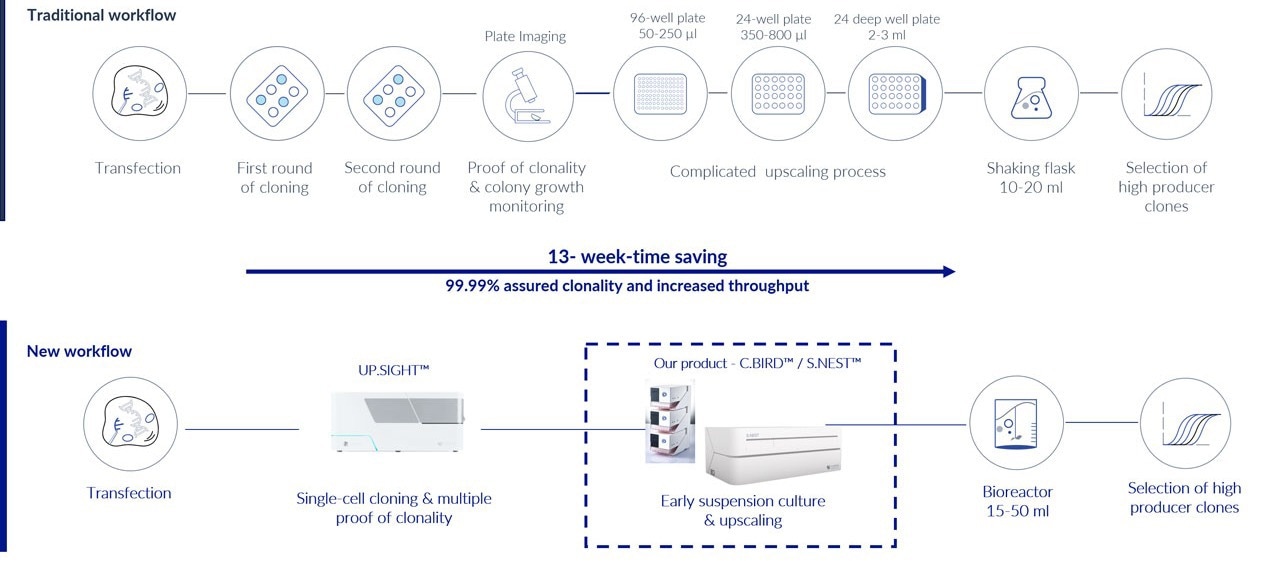

When used in conjunction with single-cell dispensers like UP.SIGHTTM, labs can save up to 13 weeks of processing time.

Image Credit: CYTENA GmbH