Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Across a wide range of pharmaceutical processes, one of the critical stages is the partial or complete removal of a solvent or solvents from a product or an intermediate. The drying process necessary can take place in several process vessels, including vacuum dryers, tray dryers and rotary dryers.

Until now, the success of the completed drying process was measured by simply taking a sample for laboratory analysis.

Gas chromatography was used to measure organic solvent concentrations in the active pharmaceutical ingredient (API) or intermediate; residual water levels were typically examined by performing a Karl Fischer titration.

The quantity of residual solvent was established by the loss on drying (LOD). If the sample failed the LOD test for one or more of the solvents, the drying process had to be completely reset. Additional complications were likely to occur in terms of both sampling the API and restarting the dryer if the drying was conducted under a vacuum.

This risk led to the tendency to increase drying times to prevent a failed LOD test, but more process challenges cropped-up. A longer drying time had an extreme effect on production lead times as the drying stage is generally a rate-limiting step during the manufacturing.

In several cases, the only way to prevent this bottleneck was to extend drying capacity at a great cost. There were also a number of instances when over-drying of the product occurred. This results in a greater risk of damaging influences on the polymorphic form of the final product and production problems later in the process.

The PAT initiative

The Federal Drug Administration’s Process Analytical Technology (PAT) initiative in 2004 highlighted the implementation of process analytical methods to optimize process understanding across the pharmaceutical industry.

For the study, the drying process was the perfect candidate, and PAT teams commenced the search for appropriate methods for continuous process analysis.

Disadvantages of spectroscopic techniques

To begin with, a number of PAT teams investigated spectroscopic methods such as near infra-red (NIR) technology for product drying. On the surface, as direct sampling was conducted in the bulk API, these methods seemed attractive. Yet, there were a number of limitations to this approach. These included:

- Retractable probes are needed to prevent damage to the probe caused by the rotating paddles in the case of paddle dryers.

- Several API drying processes require the removal of two or more solvents from a potential list of over 30 compounds, necessitating complex chemometric modeling to turn the spectroscopic data into process-friendly concentration data.

- The API coats the sampling probes

- The probe only generates a ‘spot’ sample and is not representative of the complete residual solvent in the product.

Advantages of mass spectrometry techniques

Gas analysis that uses process mass spectrometry provides simple advantages across both data manipulation and sampling, including:

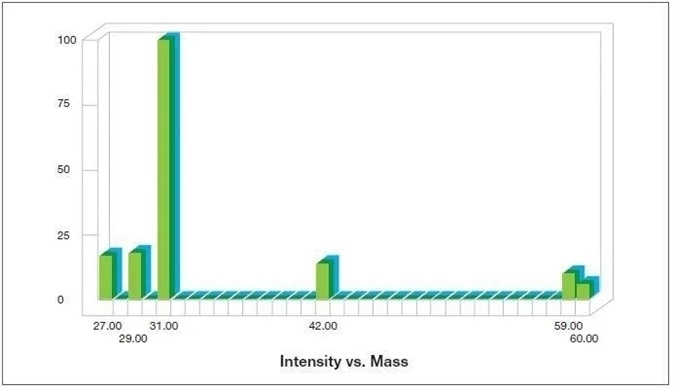

- Ability to simplify the analysis of even complex mixtures by using the fragmentation patterns of the molecules in the mass spectrometer’s ion source, which are effective ‘fingerprints.’ For example, figure 1 highlights the fragmentation pattern for n-propanol while figure 2 shows that of isopropanol.

- Acquisition of samples from the headspace above the product to guarantee effective measurement of the bulk product in the dryer and to reduce the number of problems that arise from a lack of homogeneity in the product.

- Assembling samples at the dryer outlet, either in the outlet airline or vacuum suction line, is an effortless and simple procedure that only necessitates a heated sample line, a Swagelok™ type connection and a standard particulate filter with a disposable element.

- Feasible sampling from vacuum drying processes functioning at high vacuum pressure usually ranges 10-5 to 10-6 mbar.

- Verification of vacuum integrity, either by helium leak checking or by looking for air leaks.

Although a good range of understanding and data was generated by implementing gas analysis mass spectrometers on drying processes, over time, several users experienced problems, which were in three main categories:

- Contamination of the mass spectrometry analyzer

- Converting mass spectrometry data into concentration data

- Issues with sampling over wide pressure ranges

Figure 1. Fragmentation pattern for n-propanol as generated by the Thermo Scientific™ GasWorks Software. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Figure 2. Fragmentation pattern for isopropanol as generated by the Thermo Scientific™ GasWork Software. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Analyzer contamination

The early mass spectrometers that were used for solvent drying were universally based on quadrupole analyzers. This kind of analyzer is infamously prone to contamination by hydrocarbons that lead to analyzer drift and necessitate taking the mass spectrometer offline for cleaning.

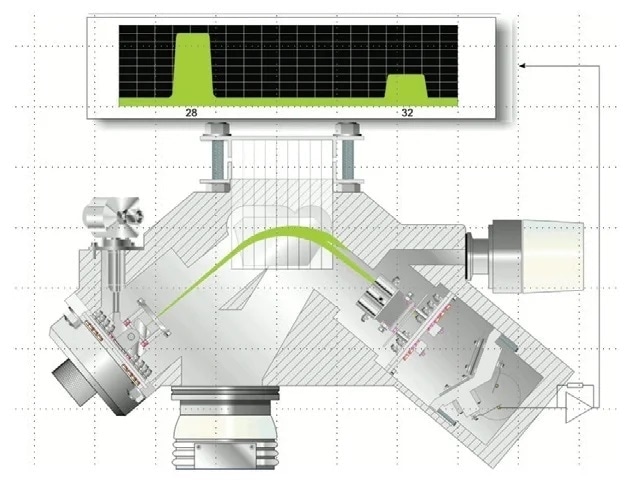

The Thermo Scientific™ Prima™ PRO Process Mass Spectrometer is a very dependable alternative with great accuracy while featuring a magnetic sector analyzer, as illustrated in Figure 3.

Figure 3. The magnetic sector analyzer within the Prima PRO Process Mass Spectrometer. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Figure 3. The magnetic sector analyzer within the Prima PRO Process Mass Spectrometer. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

The magnetic sector analyzer is predicated on experience spanning thirty years of industrial mass spectrometry and has been proven to offer unparalleled performance for online industrial gas analysis.

Some major advantages of the magnetic sector analyzer include improved accuracy and precision, long intervals between calibrations and resistance to contamination. Typically, analytical accuracy is between 2 and 10 times better than a quadrupole analyzer, depending on the gases and complexity of the mixture being analyzed.

A special feature of the analyzer’s magnet is that it is laminated, and its scanning speed is equivalent to that of quadrupole analyzers, offering the unique combination of high stability and rapid analysis.

This combination facilitates extremely stable analysis of an unlimited number of user-defined gases at high-speeds.

To achieve exceptionally stable mass alignment, the scanning magnetic sector is managed with 24-bit precision via a magnetic flux measuring device. The ion source encapsulated within the analyzer also facilitates high sensitivity, minimum background interference and optimal contamination resistance.

This high-energy (1000 eV) analyzer has demonstrated the ability to monitor high percent level concentrations of organic compounds without coming up against drift or contamination and offers a robust performance that is extraordinary in the presence of vapors and gases; those which can potentially contaminate the internal vacuum components.

Sampling from vacuum drying processes

In principle, the mass spectrometer is perfect for monitoring vacuum processes as the analyzer itself is functioning at a high vacuum.

Yet, it is vital that the pressure in the mass spectrometer remains constant as the process pressure adjusts from atmospheric down to the vacuum levels necessary to dry the product.

The signals will fluctuate in line with the sample pressure if the pressure within the mass spectrometer is not managed, leading to the output data being rendered useless.

Early mass spectrometry vacuum drying systems utilized a single control valve, typically a voltage-sensitive orifice (VSO) valve, which was connected to a gauge monitoring the sample pressure.

The VSO valve opened and closed as the sample pressure adjusted in order to sustain a persistent pressure in the mass spectrometer. Its function was sufficient for simple vacuum processes, but it suffered from a range of critical limitations, these included:

- For users who require the monitoring of numerous dryers, it was necessary to switch the mass spectrometer between a dryer at high pressure at the start of the drying cycle and a dryer at low pressure at the end of its cycle. The control valve was forced to rapidly balance these pressure swings immediately, but the response characteristics of a single valve not appropriate for this kind of duty; long delays have to be integrated into the stream switching times, especially as the solvents are at the extreme opposite ends of the concentration range.

- The valve was almost completely open at low pressures, usually lower than 10 mbar, which limited the amount of control available. The valve was 100% open at approximately 5 mbar, meaning control of the mass spectrometer pressure was non-existent below this point.

Thermo Scientific Prima PRO Process Mass Spectrometer. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Variable pressure inlet

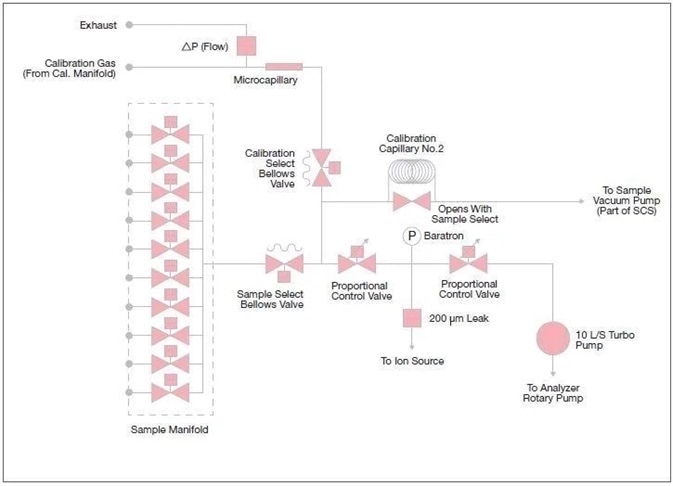

Inside the Prima PRO mass spectrometer analyzer, the variable pressure inlet is comprised of two control valves that function in opposition; one valve closes as the other opens. This combination supplies rapid control with an accurate and wide dynamic range.

The inlet manages the analyzer pressure at just 0.1 mbar, so it can withstand sample pressures down to 0.3 mbar.

Figure 4 demonstrates how the variable pressure inlet is in schematic form and Figure 5 shows the Prima PRO mass spectrometer equipped with the multipoint inlet that has the capacity to sample from up to 10 dryers. A single point inlet is also available for R&D and pilot plant users,

Figure 4. A schematic diagram of the variable pressure inlet within the Prima PRO Process Mass Spectrometer. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Figure 5. The Prima PRO Process Mass Spectrometer with the multipoint variable pressure inlet attached. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Using mass spectrometry data to control the drying process

By monitoring ion currents from the principal peaks of the solvents of interest, early mass spectrometers used for solvent drying only provided qualitative information.

While users were aided by this information by coming to an understanding of the dynamics of the drying process, the analyzer drift and resulting lack of repeatability between drying runs inhibited the acceptability of the method for process control.

In some instances, the nitrogen signal at mass 28 was used as an internal standard to generate a ‘relative response,’ but this data was not consistently accessible. It was not helpful in the instances where one peak could not be uniquely assigned to one solvent as there was considerable overlap between the fingerprints of the solvent.

When using the Prima PRO mass spectrometer, the variable pressure inlet allows for the introduction of calibration gases under software control, enabling the Thermo Scientific GasWorks software to provide solvent concentrations instead of solvent ion currents.

The special combination of accurate inlet pressure control, magnetic sector stability and GasWorks quantitative software makes sure that the process data the Prima PRO mass spectrometer provides is both precise and reliable.

There is a diverse range of industry-standard communication protocols that facilitate the transfer of this data to process control systems to improve drying processes – with which GasWorks software is totally CFR 21 Part11 compliant.

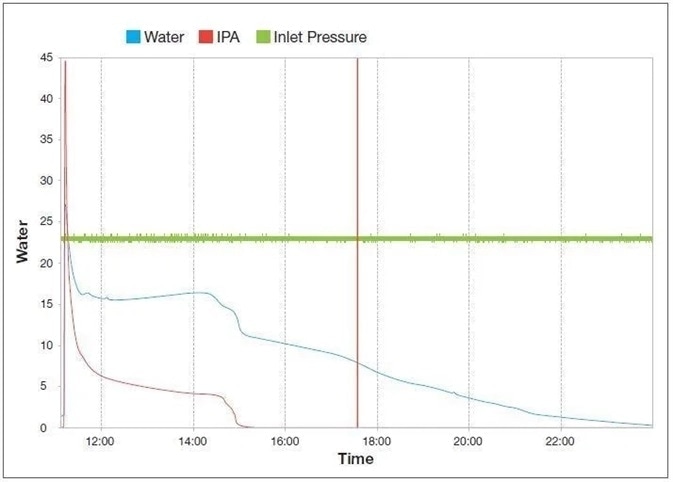

Figure 6 illustrates an example of a standard two-solvent drying curve. It demonstrates the removal of water and isopropanol as the pressure falls from atmospheric to 2 mbar. During the process, the inlet pressure remains the same at 0.1 mbar.

Figure 6. Two-solvent vacuum drying curve indicating the removal of water (blue line) and iso-propanol (red line) as the pressure drops from atmospheric to 2 mbar while the inlet pressure (green line) remains constant at 0.1 mbar. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Summary

The Prima PRO process mass spectrometer offers the most superior online measurement stability and precision available for dryer process monitoring and control.

Its fault-tolerant design, in conjunction with extended intervals between maintenance and simplified maintenance procedures, facilitate maximum availability of the analyzer.

Figure 7 highlights the plug-n-play standard service kit supplied with each unit. The dependability of the Prima PRO mass spectrometer is expressed via the industry-best three-year parts and labor warranty.

Figure 7. Prima PRO Process Mass Spectrometer service kit. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Acknowledgments

Produced from materials originally authored by Graham Lewis from Thermo Fisher Scientific.

About Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

We design and manufacture industry-leading products for Gas & particulate pollutants, Flow, gas and liquid measurement, Process analytical measurements, and Industrial Hygiene.

We design and manufacture industry-leading products for Gas & particulate pollutants, Flow, gas and liquid measurement, Process analytical measurements, and Industrial Hygiene.

Technologies have proven to help customers improve efficiency, ensure process and quality control, maintain regulatory compliance, and increase worker safety.

Process mass spectrometers

Maximize product yield and increase profitability with process mass spectrometry analysis. Process gas analyzers are engineered to meet a number of challenging process applications in the petrochemical, iron, and steel, and biotechnology industries. Highly reliable and easy-to-own, Thermo Fisher Scientific process gas analysis technologies deliver faster, more complete, lab-quality online gas analysis and process analytics. Learn More

Process Analytical Technology/Biopharma

Process Analytical Technology (PAT) is a regulatory framework initiated by the United States’ Food and Drug Administration (FDA) that encourages pharmaceutical manufacturers to improve the process of pharmaceutical development, manufacturing, and quality control.

PAT aims to improve process efficiency by defining Critical Process Parameters (CPP) and monitoring these CPPs to stay within a defined limit, either in-line or on-line to maintain a product’s Critical Quality Attributes (CQA). Monitoring CPPs with process mass spectrometry gas analysis reduces over-processing, pinpoints contaminants, and increase product consistency. Learn More

Industrial hygiene

Industrial hygiene instruments keep your investments secure, your facilities compliant with local regulations, and your workers safe from leaking pollutants, gases, or toxic vapors. Make sure you have the most updated technology, with access to repair and calibration support to maintain reliable gas monitoring. With our environmental expertise, you can breathe easy knowing your company, workers, and neighboring communities have cleaner, safer, and healthier air quality. Learn More

Sulfur analyzers

Online sulfur analyzers replace expensive and time-consuming laboratory sampling. Get fast responses and wide measurement ranges of trace sulfur and total sulfur in flare gas, liquid, and vapor for reliable emissions monitoring. Learn More

Gas & particulate analyzers

Increasingly stringent regulatory requirements are making it more difficult to maintain regulatory compliance and optimal process performance. Air quality monitoring and reporting requirements in the U.S., China, India, Europe, and Latin America are shifting and being redefined. Together we can arrive at solutions that make sound business sense. Learn More

Flow measurement

Flow measurement and process control are critical aspects of producing, handling, and transporting hydrocarbons around the world. With our Thermo Scientific suite of flow computers and flow meters, we enable our customers to reduce cost, decrease lost material, automate, and monitor critical points in processes. From field to control room and upstream to downstream, our products provide greater control, confidence, and reliability. Learn More

Sponsored Content Policy: AZO Life Science publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of AZO Life Science, which is to educate and inform site visitors interested in medical research, science, medical devices, and treatments.