Produced in Partnership with RETSCH GmbHReviewed by Emily MageeNov 17 2025

Drug discovery (the discovery of new drugs) is an intricate process spanning basic research to preclinical assessment and clinical trials. At every stage, accurate and reproducible sample preparation is essential as it can directly impact research outcomes.

Retsch’s customized solutions are designed to boost both the efficiency and quality of your processes, from the initial sample preparation all the way to the final, market-ready formulation.

Targeted Particle Size Control to Maximize Bioavailability and Efficacy

Retsch mills allow researchers to grind active pharmaceutical ingredients (APIs) and excipients to the exact particle size that is required. This optimizes bioavailability, improves solubility, and ensures uniform drug distribution in the body. Mixing is equally reliable, providing the ideal foundation for tablets, capsules, or liquid formulations.

Retsch’s new sieving machines make particle size analysis easier and more precise than ever. This means that users can now determine even the finest particle distributions while meeting strict regulatory standards, which is ideal for applications with tight specifications, such as clinical trials or approval processes.

Advanced Techniques for Drug Development

With Retsch equipment, users are able to explore new fields of research, including:

- Mechanochemistry and Co-Crystal screening: Develop new forms of active ingredients without solvents, enhance solubility, and accurately control reaction pathways with temperature management.

- Nanotechnology: Produce highly potent compounds with optimized cell penetration and benefit from precise particle size control.

- Homogenization and cell disruption: Efficiently extract DNA, RNA, and proteins from cell suspension and tissue samples, which is key to the development of biopharmaceuticals and vaccines.

Mechanochemistry and Co-Crystal-Screening – Practical Solutions for Research

Retsch ball mills let you carry out mechanochemical reactions in a way that’s both eco-friendly and efficient. You can accelerate results, conserve resources, and precisely control reaction pathways through temperature regulation. For instance, metastable intermediates in mechanochemical reactions have been successfully stabilized and recovered by maintaining temperatures around -5 °C using the MM 500 control.

Image Credit: RETSCH GmbH

Mixer Mill MM 400. Image Credit: RETSCH GmbH

Co-Crystal screening is highly efficient with Retsch’s setup. Using a special adapter, you can screen up to 64 samples at once in the PM 400 planetary ball mill, a process that also works with the PM 100 and PM 300 models.

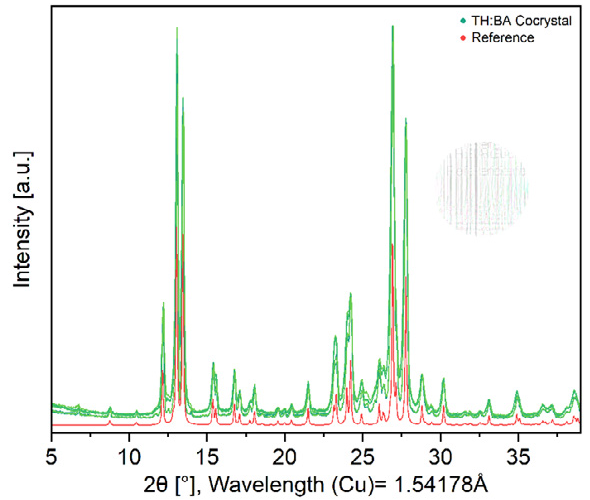

Co-Crystals can be produced just as reliably in mixer mills like the MM 400. In one study, for example, theophylline and benzamide were combined in a 1:1 ratio using 2 ml steel tubes and 6 mm steel balls at 30 Hz for 60 minutes. The resulting X-ray powder diffraction patterns matched the reference data exactly, giving reproducible and reliable results every time.

XRD pattern after Co-Crystal formation of theophylline and benzamide after 60 minutes of grinding in the MM 400, compared to a simulated reference. Results presented by experiments conducted by Dominik Al-Sabbagh.1 Image Credit: RETSCH GmbH

Nano-Grinding and Mixing – Accuracy and Versatility for Formulations

High-performance ball mills such as the Emax, the PM series, and the MM 500 nano/control enable the production of nanoparticles under 100 nm with narrow particle size distributions for novel drug formulations.

For example, 12 g API (15 μm particles) were ground with 26 ml heptane and 110 g of 0.5 mm zirconium oxide grinding balls in the Emax at 2000 rpm for two and a half hours. The outcome was an extremely narrow particle size distribution with a D90 value of 80 nm. Integrated water cooling and optional chillers protect temperature-sensitive samples, allowing continuous operation without unnecessary grinding breaks.

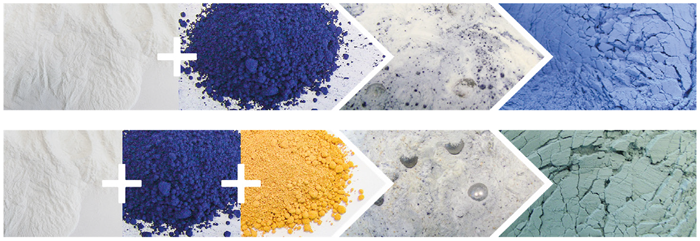

Mixing active ingredients with excipients is also efficient. In the PM 400, 196 g of starch was perfectly mixed with four g of pigment in a 500 ml grinding jar with 200 10 mm grinding balls. This process took only five minutes at 200 rpm and resulted in no particle size reduction.

Top: Starch and blue Pigment after 5 minutes of milling in the PM 400. Bottom: Starch, blue & yellow pigment after 5 minutes of milling in the PM 400. Image Credit: RETSCH GmbH

Efficient Cell Disruption and Tissue Homogenization – Foundations for Biopharmaceuticals

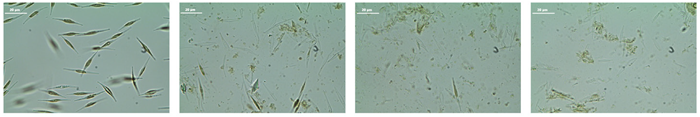

Retsch mills facilitate the efficient, reproducible release of DNA, RNA, and proteins from samples while preventing cross-contamination. The bead-beating technique allows various cell types to be broken down in parallel, from bacteria and yeast to fungi and algae.

Flexible, small-scale processing is enabled by 2 ml Safe-Lock reaction vials, while 50 ml conical centrifuge tubes support larger-scale work. Tissue samples such as liver or lung can be homogenized using the MM 400 and MM 500 vario.

For temperature-sensitive samples, the CryoMill employs liquid nitrogen cooling to -196 °C, optimally preserving biomolecule integrity. The MM 500 control enables cryogenic processing of up to 2 x 20 ml of cell suspension (temperature range of 0 °C to -100 °C) or cooled, for example, at 10 °C.

Cells of Phaeodactylum tricornutum before (left) and after cell disruption (right) with the MM 400 in combination with the Falcon tube adapter. Image Credit: RETSCH GmbH

Innovation in Sieving – Reliable Particle Size Analysis and GMP Conform

The AS 200 jet pharma air jet sieving machine delivers precise, automated, and GMP conform particle size analysis. It integrates sieving, weighing, and evaluation into one instrument while offering the advantages of integrated wizards, audit trails, and e-signatures. Results are fully documented and can be exported directly to LIMS.

Air Jet Sieving Machine AS 200 jet pro. Image Credit: RETSCH GmbH

Conclusion – The Advantage of Pharmaceutical Active Ingredient Research with Retsch

Retsch technologies help boost the efficiency and reproducibility of your processes, from sample preparation to particle size analysis. You can easily integrate the latest methods into your research, take advantage of practical, user-friendly solutions, and ensure consistent, reliable results. With Retsch as your partner, you’ll move through drug development faster, with greater precision and confidence.

About RETSCH GmbH

With more than 100 years of experience in sample preparation, RETSCH is the world’s leading manufacturer of instruments for homogenizing laboratory samples for analysis as well as for analyzing the particle size of solid substances by test sieving.

The RETSCH product portfolio includes a great variety of mills and jaw crushers, capable of reducing materials down to any required fineness, sieve shakers and test sieves as well as assisting technologies to optimize the handling of samples.

RETSCH instruments stand for representative sample preparation in compliance with relevant standards and contamination-free comminution processes – they are essential tools for preparing samples for laboratory analysis and stand for reliability, precision and durability.

Since 1990 RETSCH is part of the continuously growing technology group VERDER and forms the core of the group’s Laboratory Division VERDER SCIENTIFIC. Other companies belonging to this division are Retsch Technology GmbH, ATM GmbH, Eltra GmbH and Carbolite Gero Ltd.

RETSCH company video - Solutions in Milling & Sieving

Sponsored Content Policy: AZoLifeSciences publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of AZoLifeSciences which is to educate and inform site visitors interested in life science news and information.