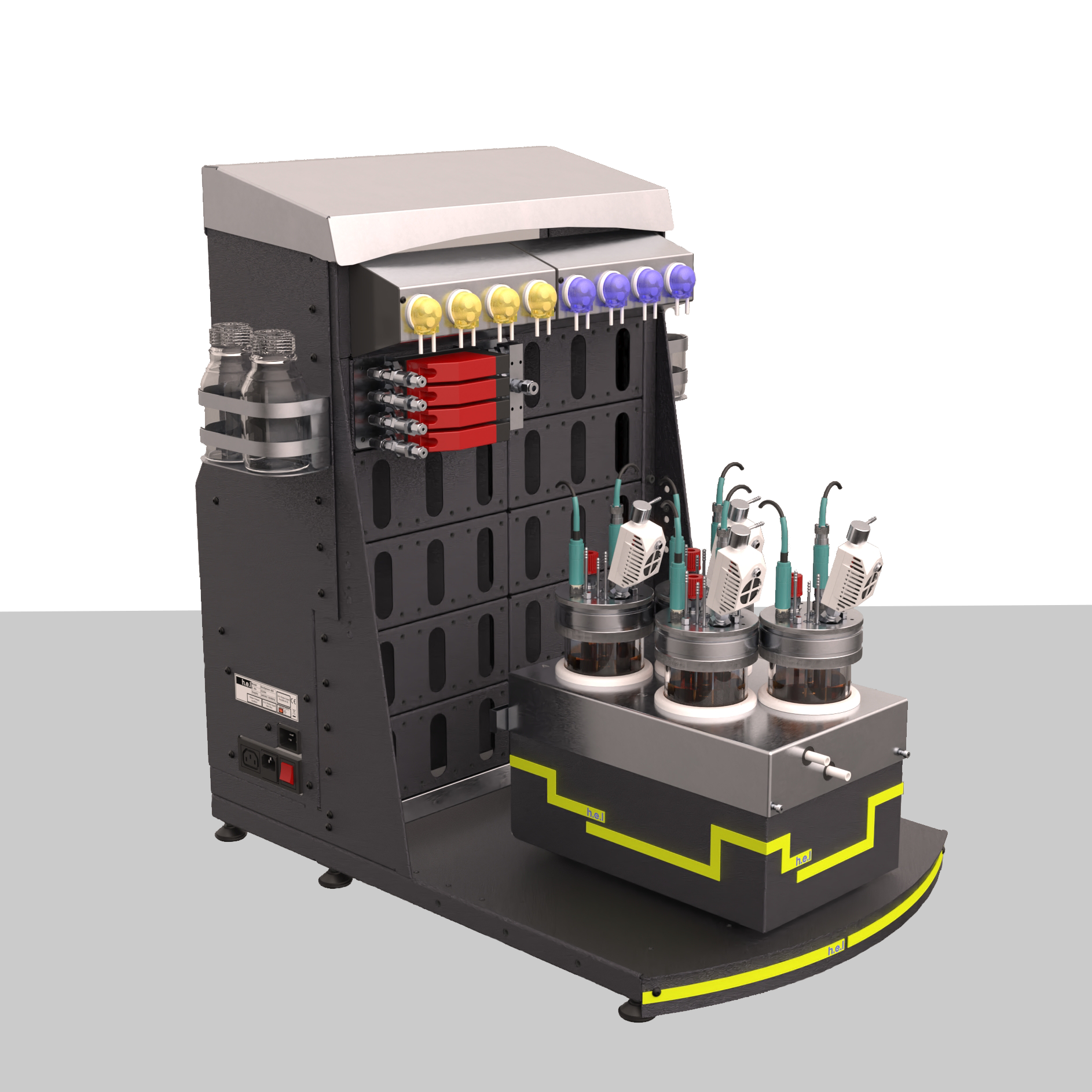

The BioXplorer 400 from H.E.L Group has been fitted with four bioreactors with up to 400 ml working volumes. It is an excellent tool for parallel bioprocess optimization.

The highly configurable nature of their lid extends the testing capability for the bioprocess, selecting which probes to utilize to specify in real time the vital parameters for the fermentation. Integrated with H.E.L’s WinISO, it enables the complete automatization of aerobic fermentation.

BioXplorer 400 from H.E.L Group. Image Credit: H.E.L Group

BioXplorer 400 from H.E.L Group. Image Credit: H.E.L Group

Overview

Parallel Bioreactor

The BioXplorer 400 has four bioreactors that can hold between 120 ml and 400 ml of liquid. These bioreactors are explicitly designed for aerobic fermentation. They serve as the basis for bioprocessing projects, enabling the user to run up to four bioprocesses at the same time. The BioXplorer 400 provides numerous options for conducting detailed experiments, screening multiple samples at once, or speeding up the research.

Flexibility and Control

The extensive range of probes available with the BioXplorer 400 allows the tracking of vital parameters for the bioprocess for in-depth characterization. The responsiveness of WinISO enables the fine control of vital parameters in fermentation by implementing automated feedback loops.

BioXplorer 400 is a fantastic tool for characterization and optimization of processes. The customizable configuration of the bioreactors enables the cautious selection of the parameters to track at the time of the fermentation.

Having a choice of agitation, either magnetic or overhead, allows an extensive range of impellor speeds, enabling the cultivation of shear sensitive cells at lower speeds. Greater impellor speeds increase gas transfer for high product yields or cell densities.

Features and Options

Source: H.E.L Group

| Specification Point |

BioXplorer 400 |

| Number of independent parallel bioreactors |

4 |

| Bioreactor material |

Glass body, stainless steel lid |

| Total volume |

500 ml |

| Working volume |

120 – 400 ml |

| Sterilization |

Autoclavable bioreactors (including sensors) |

| Temperature Range |

0 – 135 °C |

| Temperature resolution |

0.1 °C |

| Stirrer drive |

Magnetically driven captive impeller or Overhead agitation (magnetically coupled) |

| Stirrer speed |

- Magnetically Driven – 250 – 1500 rpm

- Overhead Agitation – 20- 2000 rpm

|

| Liquid additions with independent control for each bioreactor |

2 as standard, options for upto 2 additional liquid feeds |

| Gas additions |

1 set of 4 mass flow controllers allowing independent control for each reactor as standard, option for 1 additional set |

| Standard options for MFC calibration |

Air, oxygen as option |

| Gas spargers |

1 |

| Exhaust gas |

Peltier cooled condenser |

| pH control |

1-way control (2-way control optional) |

| Polarographic DO sensing |

Standard |

| DO control |

Gas/liquid flow rate, stirrer speed |

| BioVIS – Understand cell density trends without taking samples |

Optional |

| Foam/Level detection |

Optional |

| Control PC and software |

Windows® PC with WinISO control software preinstalled:

- Fully independent control of all reactors

- Advanced control strategies for stirring and liquid and gas additions based on feedback from sensors, time-based profiles, or event detection

- Real-time display and logging of all reaction parameters

- Easy export of data in a range of formats, including .csv

|

* Upper temperature limit for data acquisition from standard pH and DO probes is 60 °C and 40 °C, respectively. The lower temperature limit requires an integrated circulator option.