Reviewed by Lexie CornerJun 18 2025

Researchers at Lawrence Berkeley National Laboratory, UC Irvine, and the University of Illinois Urbana-Champaign (UIUC) have developed a method to convert human urine into a usable material.

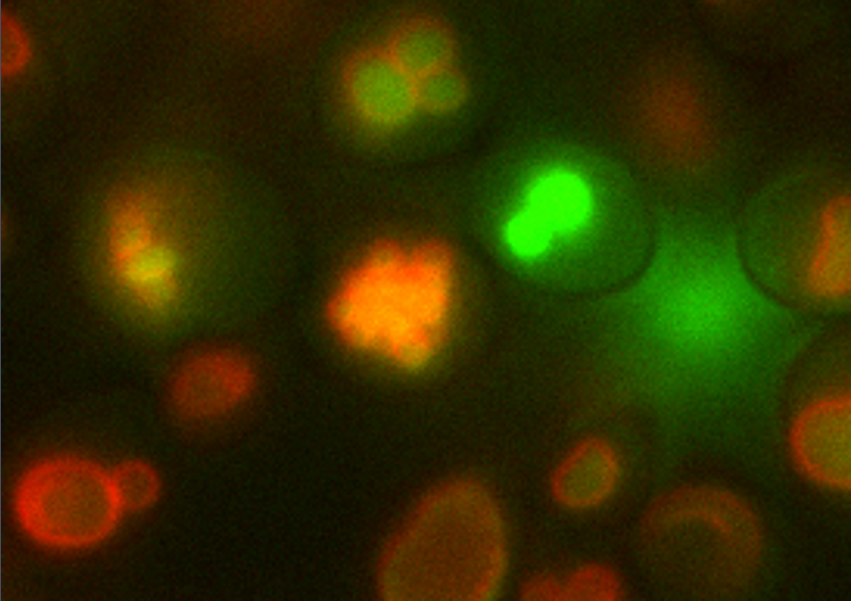

These optical microscopy images show the osteoyeast cells. The outline of the vacuole, the cellular organelle where calcium is accumulated to form hydroxyapatite, is fluorescing red. The calcium inside the vacuole is fluorescing green. Image Credit: Behzad Rad/Berkeley Lab

These optical microscopy images show the osteoyeast cells. The outline of the vacuole, the cellular organelle where calcium is accumulated to form hydroxyapatite, is fluorescing red. The calcium inside the vacuole is fluorescing green. Image Credit: Behzad Rad/Berkeley Lab

They genetically modified yeast to process components in urine and produce hydroxyapatite. This is a calcium- and phosphorus-based mineral that humans and other animals naturally use to form bones and teeth.

Commercially, hydroxyapatite is used in surgical and dental procedures to repair bone structures. Its light weight and durability also make it useful in construction and as a potential alternative to some plastics.

The team’s recent publication in Nature Communications outlines a lower-cost approach to producing hydroxyapatite. It also describes how the method could reduce the cost of wastewater treatment and provide a more energy-efficient way to produce fertilizer. In addition, the findings support the development of other yeast-based technologies that can extract useful materials from waste streams.

A Strange Brew

The focus of the study is a strain of Saccharomyces boulardii, a yeast closely related to the species commonly used in brewing and baking. This yeast naturally collects minerals from its environment and stores them in a specialized membrane compartment.

Co-authors Yasuo Yoshikuni, head of the DNA Synthesis Science Program at the Joint Genome Institute (JGI), and Peter Ercius, a staff scientist at the National Center for Electron Microscopy at the Molecular Foundry, were exploring ways to use microbes to produce functional biomaterials. During this work, they found that S. boulardii carries out processes similar to those of osteoblasts - animal cells responsible for producing hydroxyapatite and forming bone.

The JGI and the Molecular Foundry are user facilities supported by the U.S. Department of Energy Office of Science and are located at Berkeley Lab.

The serendipitous part is this yeast already had similar molecular mechanisms. Just mild tweaking was sufficient to convert the yeast into a cell factory for hydroxyapatite.

Yasuo Yoshikuni, Head, DNA Synthesis Science Program, Joint Genome Institute

The engineered organism, referred to as “osteoyeast,” mimics the function of osteoblasts - cells that are typically difficult and expensive to produce outside the body. At the same time, it retains the practical advantages of yeast, such as ease of growth and maintenance. From the beginning, osteoyeast enabled more affordable hydroxyapatite production.

The researchers saw an opportunity to broaden the impact of their work by using urine as a mineral source. This idea was influenced by a growing trend in biotechnology known as “pee-cycling,” which explores the reuse of nutrients from human waste.

It is kind of exactly what you think it is. People are trying to collect urine before it hits the sewer system to use the ammonia and phosphate in it for farming and other applications. These components cause environmental issues when wastewater enters the landscape or ocean, so treatment facilities are already spending a lot of money to neutralize urine. The idea is, why do not we put it to use?

Behzad Rad, Study Author and Principal Scientific Engineering Associate, Biological Nanostructures Facility, Molecular Foundry, Lawrence Berkeley National Laboratory

According to Yoshikuni, pee-cycling has not become widely adopted because ammonia and phosphate are inexpensive. This reduces the financial motivation to develop large-scale systems for recovering these nutrients.

However, osteoyeast offers a new use case by producing high-value hydroxyapatite from the phosphorus and calcium found in urine. Additionally, the microbes naturally collect ammonia salts within their membrane compartments, which may support further resource recovery.

Yoshikuni added, “Today, we use about 1 % of the world’s energy to make fertilizers from nitrogen gas. If we are able to produce both hydroxyapatite and nitrogen fertilizer from the ammonia, we could potentially replace a significant portion of the total nitrogen demand, saving energy while also dramatically reducing costs at wastewater facilities.”

Good Bone Structure

A key part of the project was confirming that osteoyeast could complete all steps involved in hydroxyapatite production.

Initial tests suggested promising results when Isaak Müller and Alex Lin, two postdoctoral researchers at Berkeley Lab and co-first authors of the study, detected hydroxyapatite in the culture. However, the team did not initially find the crystalline form of the material inside the yeast cells.

They observed small mineral granules forming inside the cells, but were uncertain whether the yeast was completing the crystal formation process or if a different reaction was happening outside the cells.

This part of the study was led by Ercius and Rad, using instrumentation from the Molecular Foundry.

Rad applied optical microscopy to observe yeast strains tagged with fluorescent proteins and markers.

Ercius used transmission electron microscopy (TEM) to verify that the granules inside the yeast’s storage membrane matched the composition of hydroxyapatite.

Combining these methods allowed the researchers to trace the full formation process.

Ercius also used TEM to confirm that the resulting hydroxyapatite had a consistent nanostructure and high material quality.

At the same time, Yoshikuni and Yusuke Otani - a co-first author and postdoctoral researcher at JGI - found that the engineered microbes could produce hydroxyapatite efficiently, generating one gram of the material per kilogram of urine.

Colocalization of all these facilities was key. That we were able to meet and collaborate so closely was really critical. I am not a biologist, and my colleagues are not experts in materials synthesis and characterization. This work showcases what you can achieve when you combine scientific approaches that are not typically integrated.

Peter Ercius, Staff Scientist, National Center for Electron Microscopy, Molecular Foundry

Turning Yellow Into Green

To evaluate the economic feasibility of the pee-cycling project, the Berkeley Lab team consulted co-author Jeremy Guest, Sustainable Design Lead at the DOE Center for Advanced Bioenergy and Bioproducts Innovation at UIUC. Guest and UIUC research scientist Xinyi (Joy) Zhang carried out a technoeconomic analysis. They modeled decentralized hydroxyapatite production systems for a city the size of San Francisco.

Their analysis considered the costs of cultivating osteoyeast and separating urine from wastewater. Based on these factors, they estimated that producing one kilogram of commercial-grade hydroxyapatite would cost approximately $19. In the United States, this material could be sold for between $50 and $200 per kilogram.

Overall, the system could generate an estimated annual profit of $1.4 million. It would also reduce the need for additional chemical treatments in wastewater processing.

“It is important that we consider the potential impacts of a full-scale system. We can develop a new technology and demonstrate it in the lab, but is it actually feasible? Is there an opportunity for this innovation in the real world?” emphasized Guest.

The team is working to develop additional strains of the patented osteoyeast. These new strains could be engineered to produce other bio-based materials or to capture and store specific elements, supporting environmentally friendly bio-mining applications.

The current osteoyeast strain is already available for licensing for the production of hydroxyapatite.

Source:

Journal reference:

Müller, I. E., et al. (2025) Cost-effective urine recycling enabled by a synthetic osteoyeast platform for production of hydroxyapatite. Nature Communications. doi.org/10.1038/s41467-025-59416-8.