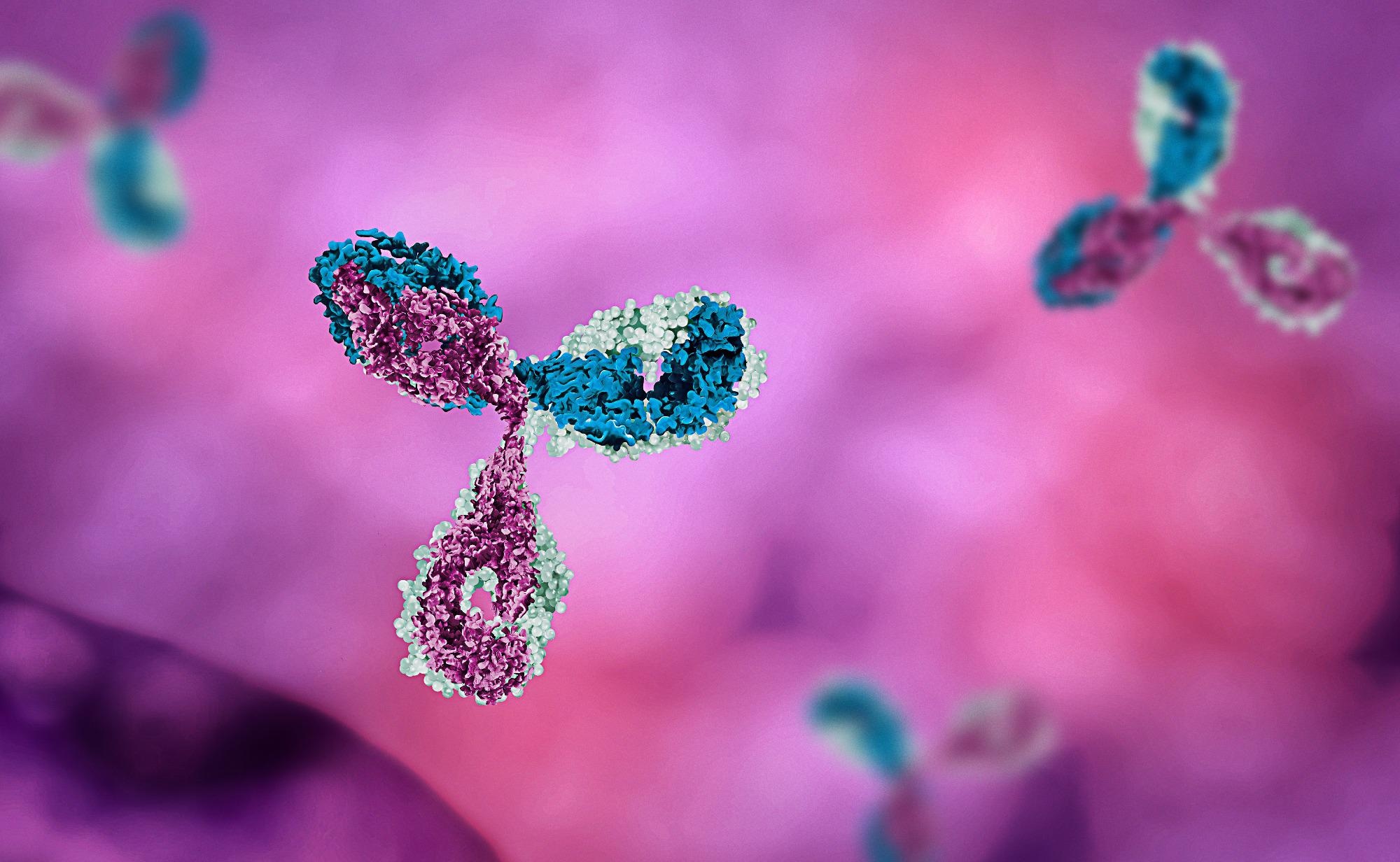

Monoclonal antibodies first arose from hybridomas, which are hybrid cells generated through the fusion of antibody-producing lymphocytes with tumor cells. Monoclonal antibodies are currently produced from the cultivation of these hybridomas. Recent research uses a range of engineered microorganisms and cells to produce monoclonal antibodies at commercial scales.

Image Credit: Mirror-Images

Monoclonal antibody production techniques

Hybridoma and phage display

The first production technology for stable monoclonal antibody production was developed in 1975 by creating a hybridoma, which is a stable hybrid cell able to produce a single antibody type against a certain epitope found in an antigen. In the early stages, the construction of hybridomas was made from murine models. This technology was based on taking out a pool of activated B lymphocytes from immunized animal spleens fusing them with immortalized myeloma cells that do not have the ability to synthesize hypoxanthine-guanine-phosphoribosyl transferase, a key enzyme found in the salvage pathway, one of the pathways needed for the synthesis of nucleotides.

The hybridoma cell selection requires the pool of cells being produced from the fusion, to be enriched in a selective media with aminopterin, a compound that can inhibit the de novo synthesis of nucleotides.

Myeloma cells do not have the salvage pathway, which is responsible for the production of nucleotides. If myeloma cells are in contact with aminopterin found in the selective medium, there will be inhibition of de novo synthesis. Therefore, myeloma cells will be not viable anymore because all main pathways for the production of nucleotides are blocked.

On the contrary, activated non-fused B lymphocytes will survive because their salvage pathways are working fine and nucleotide production will be continued even if aminopterin has blocked the de novo pathway. Yet, these activated non-fused B lymphocytes are mortal and they could replicate for only a finite number of times. Then, they will die at the end.

Cells, which are able to replicate indefinitely and synthesize nucleotides via the salvage pathway, can survive via selection conditions, and these cells are called the hybridomas. Murine antibody molecules, following a small number of infusions, could stimulate the human anti-mouse antibody response of the human immunity.

For the delivery of antibodies that are similar to human molecules, new methodologies have been evolved to produce a smaller amount of immunogenic chimeric antibodies (variable regions of the murine source are linked to constant regions of human antibodies). As a result, the requirement for less immunogenic alternatives enhanced the synthesis of humanized antibodies (just the parts that interact with antigen epitopes are from mouse origin). Genetically modified mice can synthesize fully human antibodies.

The development of phage display libraries has made great improvements in the production of monoclonal antibodies. This recent method investigates molecular interactions (protein-DNA, protein-peptide, and protein-protein) and is mainly based on cloning Fab-region-coding genes amplified from B lymphocytes into phage vectors. Following this, the bacteria could be transformed with these vectors for expressing the heterologous genes from viral capsids, which have viral proteins and proteins encoded by the Fab sequence taken by these particular cells.

After the completion of the library, the affinity between proteins synthesized from various Fab regions could be examined against the particular antigens and the cell transformed with plasmids that have those genes can be easily sequenced. This method has many advantages such as the potential to produce a high number of new antibodies and no requirement of animal immunizations steps.

Culture production factors

The choice of the appropriate cell line is one of the most critical procedures in developing monoclonal antibodies. The mammalian cells, which are stable and can secrete the required protein with the appropriate conformation at great amounts, are the most commonly chosen expression systems for the production of monoclonal antibodies.

Adaptation for the synthesis, processing and secretion of highly complex molecules can be considered the main advantage of a mammalian expression system. Two cell hosts are predominantly utilized to synthesize monoclonal antibodies; Chinese hamster ovary (CHO) cells and murine myeloma (NS0) cells (non-Ig secreting, non-light chain-synthesizing subclone of NS-1).

Genetic modifications in CHO cells have generated cell lines that are able to produce a great amount of humanized monoclonal antibodies. These cell lines can secrete up to 100 pg/cell/day. Microorganisms adapted through genetic manipulation technologies have great potential in industry since these cells are easy to manipulate and alter in comparison with animal cells. These cells also have distinct expression systems, and the production method is easy to validate and reproducible.

Complex ingredient contents which range from amino acids to trace elements must be found in the cultivation media for mammalian cells. Therefore, the serum is used to provide these nutrients to the cells. Yet, owing to the disease emergence that occurred through defective prions, such as bovine spongiform encephalitis, removal of any animal components of culture medium should be performed, particularly if the medium will be utilized for biopharmaceutical industrial products.

Preparation of an appropriate medium can be very expensive and time-consuming. The conditions of mammalian cell culture for monoclonal antibody production are sharply defined; pH 7.15, temperature 37 °C, and dissolved O2 level at 30–60%.

The level of CO2 should be observed to imitate the physiological criteria (31-54 mmHg). Growing conditions can directly affect the growth of cells and production levels.

Sources:

- Carvalho, L. S., da Silva, O. B., de Almeida, G. C., de Oliveira, J. D., Parachin, N. S., & Carmo, T. S. (2017). Production processes for monoclonal antibodies. Fermentation Processes, 182-198. DOI: 10.5772/64263. https://www.intechopen.com/chapters/51512

- Chames, P., Van Regenmortel, M., Weiss, E., & Baty, D. (2009). Therapeutic antibodies: successes, limitations and hopes for the future. British journal of pharmacology, 157(2), 220-233. https://doi.org/10.1111/j.1476-5381.2009.00190.x

- Chartrain M, Chu L. Development and production of commercial therapeutic monoclonal antibodies in Mammalian cell expression systems: an overview of the current upstream technologies. Curr Pharm Biotechnol 2008;9:447–67. doi:10.2174/138920108786786367

- Liu, J. K. (2014). The history of monoclonal antibody development–progress, remaining challenges and future innovations. Annals of medicine and surgery, 3(4), 113-116. https://doi.org/10.1016/j.amsu.2014.09.001

Further Reading

Last Updated: Dec 17, 2021