Three-quarters of the biomass produced by hop plants used in beer production is disposed of in landfills. However, a team of Japanese researchers has devised a method for converting discarded hop into cellulose nanofibers (CNFs). The technique was described in a paper published in the journal ACS Agricultural Science & Technology.

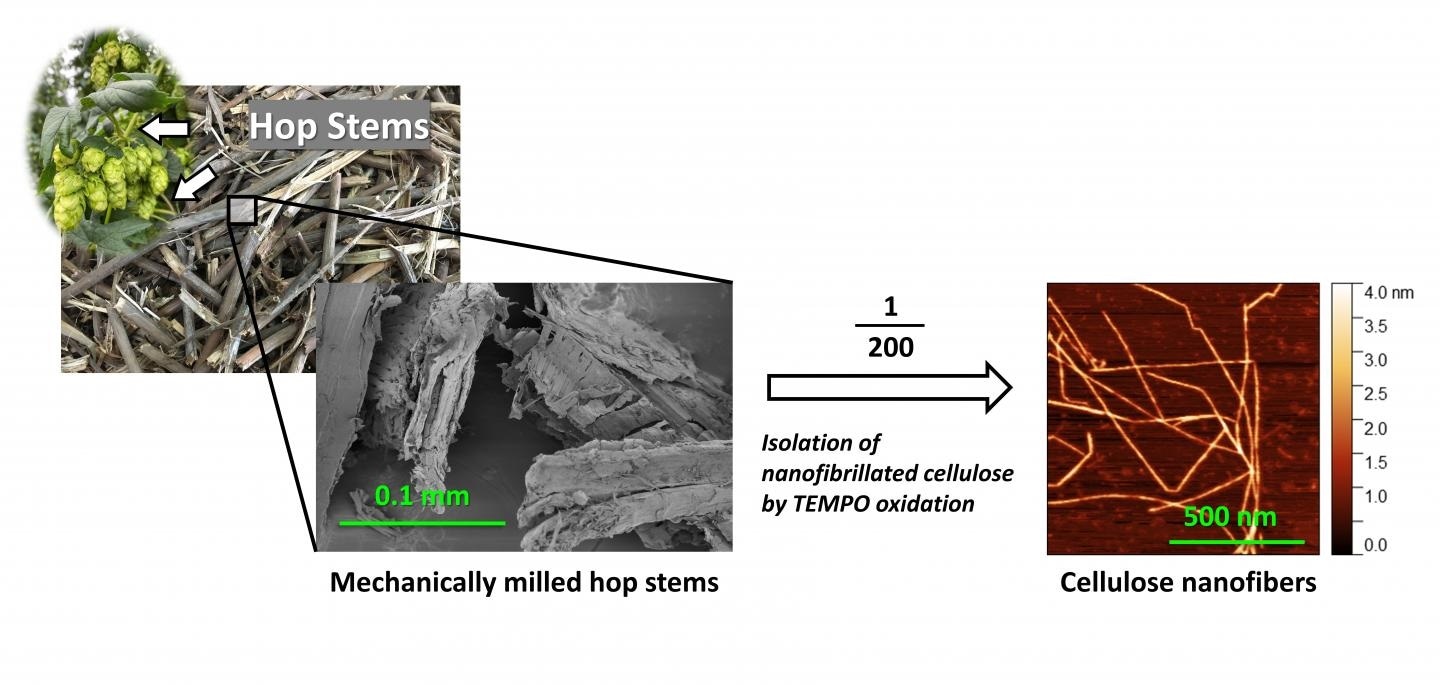

Cellulose nanofibers were produced from waste hop stems by TEMPO-mediated oxidation. Image Credit: Yokohama National University.

Craft beer has gained wider popularity around the world in recent years, with many beer styles utilizing considerably more and different types of hops than traditional commercial beers. Hops are a traditional beer preservative that also offers a deep bitterness and floral or citrus scents and flavors. As a result, 2019 saw a new high in hop production.

In the production of beer, however, only the blossom of the hop plant is used. After harvest, the stems and leaves, which make up around 75% of the biomass produced in hop production, are usually burned or thrown in a landfill.

Because over 75% of hop plants end up in landfills, the technology should help to minimize the beer industry’s expanding waste and land impact while also reducing petroleum feedstock consumption.

A group of researchers has devised a method for “upcycling” these waste products by extracting CNFs from hop stems as a raw material. Due to their remarkable qualities, such as low weight, great strength, and stability, CNFs have sparked increased interest since the 2000s.

CNFs are predicted to be used as good plant-derived materials for lowering the number of petroleum-based plastics in a variety of industrial applications, including the automotive and housing industries, as well as the food and cosmetic domains, as a result of these advantages.

This really would deserve a hearty ‘cheers’ if we managed to reduce dependence on petroleum while also radically reducing the agricultural waste from the beer industry.”

Izuru Kawamura, Lead Researcher and Associate Professor, Graduate School of Engineering Science, Yokohama National University

CNFs had previously been successfully recovered from wood and agro-industrial wastes such as pineapple leaves, banana stems, grapefruit peels, and even cafe wasted coffee grounds.

But until now, no attempt had been made to isolate CNFs from hop stems.”

Izuru Kawamura, Lead Researcher and Associate Professor, Graduate School of Engineering Science, Yokohama National University

Cellulose microfibrils, or very short and thin fibers, are embedded in a matrix of lignin and hemicellulose in plant cell walls. Depending on the source of the fibers, the chemical compositions of cellulose, hemicellulose, and lignin differ significantly.

CNFs are typically recovered from wood pulp by a series of purification procedures, followed by refining via chemical or enzyme treatment. Previously, a process involving the application of the 2,2,6,6-tetramethylpiperidine-1-oxyl radical (referred to as “TEMPO”) to cellulose prepared from wood and moderate mechanical disintegration in water yielded CNFs of 3–4 nm in width.

Prior to the TEMPO stage, the researchers applied the TEMPO approach but lowered the pretreatment processes for removing lignin and hemicellulose from hop stems, which are considered lignocellulose fibers. They were able to obtain CNFs with a median of roughly 2 nm even without the pretreatments.

From the chemical composition analysis, they were able to determine that the hop stems included a fraction of cellulose that was nearly equal to that of wood.

This indicates that not only might this approach replace petroleum, but hop waste could also be utilized instead of wood as a source for CNFs, resulting in a triple environmental win.

You might even say ‘three cheers’ for CNFs from hops.”

Izuru Kawamura, Lead Researcher and Associate Professor, Graduate School of Engineering Science, Yokohama National University

The team plans to prepare various emulsions stabilized by hop stem-derived CNFs and demonstrate their viability to the industry as a future step. They should result in a large reduction in the amount of conventional synthetic surfactants utilized if they are successful.

Source:

Journal reference:

Kanai, N., et al. (2021) Upcycling of Waste Hop Stems into Cellulose Nanofibers: Isolation and Structural Characterization. ACS Agricultural Science & Technology. doi.org/10.1021/acsagscitech.1c00041.