By Pooja Toshniwal PahariaReviewed by Lauren HardakerJul 23 2025

By Pooja Toshniwal PahariaReviewed by Lauren HardakerJul 23 2025In a recent study published in Foods, researchers developed innovative multilayer biodegradable films of chitosan (CH) and polycaprolactone (PCL) fibers for food packaging. Layering CH and PCL offers a compelling solution for sustainable food packaging. The enhanced mechanical strength, barrier properties, and modifiable biodegradability address key limitations of existing biodegradable materials, paving the way for more eco-friendly and effective packaging solutions in the food industry.

Image credit: UladzimirZuyeu/Shutterstock.com

Image credit: UladzimirZuyeu/Shutterstock.com

The buildup of plastic waste in landfills and aquatic environments is contributing to pollution, climate change, and the disruption of ecosystems. Microplastics from plastic packaging persist in the environment for extended periods, contaminating soil, water, and air. These microplastics can enter the food chain, harm wildlife, and affect human health.

Research has focused on developing biodegradable films to address these issues; however, their poor barrier functions and mechanical properties limit practical utility. Biodegradable films break down naturally, reducing plastic pollution and waste, and can contribute to soil health. Moreover, they can be made from renewable resources, reducing their carbon footprint and potentially improving human health by reducing exposure to harmful chemicals.

About the Study

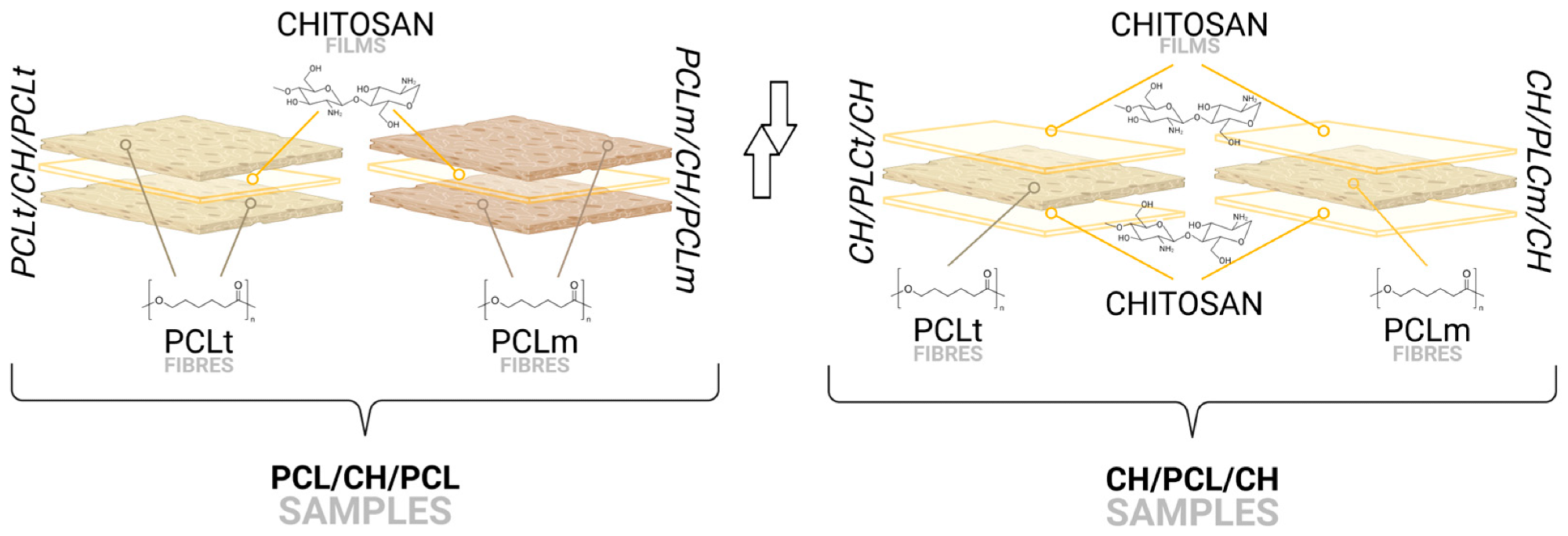

The present study introduces an innovative technique for generating multilayer biopolymer films by electrospinning PCL fibers in a CH matrix. The team investigated two patterns: one involved non-woven PCL fiber layers between CH sheets, and the other comprised a CH sheet between non-woven PCL layers on both sides. Both technical-grade and medical-grade polycaprolactone polymers were used, which differ in purity and crystallinity, influencing the mechanical and degradation properties of the resulting films. They thermally welded the layers at the melting point of PCL to yield the final product.

The researchers prepared CH films by mixing CH (MW = 250,000 g/mol) with acetic acid and glycerol. Combining 99.9% chloroform with 99.9% acetone dissolved the polymer materials. Film production required 10 mL/hour flow rate, 0.8-1.3 kV voltage, 24°C, and 34% relative humidity.

The team analyzed the films' mechanical, barrier, hydrophilic, optical, thermal, and structural properties. They compared the results to monolayer CH films comprising non-electrospun PCL fibers. Barrier properties included carbon dioxide permeability, water vapor permeability (WVP), oxygen permeability, and water vapor transmission rate (WVTP). Hydrophilic properties investigated included the moisture content (MC), degree of swelling (SD), total soluble matter (TSM), and the dynamic water contact angle of the films.

Spectrophotometry enabled the determination of light absorption by the films. To monitor hydrolytic degradation, the team simulated physiological conditions using phosphate-buffered saline (PBS) and measured mass loss from the biopolymer films over three consecutive days. They performed scanning electron microscopy (SEM) to examine the structure of the prepared films.

Schematic representation of obtained films’ layer configurations. Image credit: Innovative Multilayer Biodegradable Films of Chitosan and PCL Fibers for Food Packaging

Results

The CH/PCL/CH arrangement (chitosan sheets sandwiching a medical-grade PCL fiber layer), demonstrated superior results with enhanced cohesion between the layers and improved durability, mechanical strength, and barrier functions. The porous PCL fiber mat enhanced flexibility and energy absorption, while the CH layers provided stiffness and surface functionality.

The mechanical performance of the multilayer films strongly depended on the internal structure: in the CH/PCL/CH configuration, strong adhesion was observed between layers, while in the PCL/CH/PCL configuration, the layers often suffered from delamination and poor interfacial adhesion.

The CH/PCL/CH configuration demonstrated a 36% fracture strain (elongation at break) and a tensile strength of 57 MPa, more than twice that of CH-only films. This indicates that the biopolymer films can withstand the stress of handling, transportation, and storage. A lower contact angle of 102.5◦ in this configuration (vs. 130-133◦ in the PCL/CH/PCL configuration) improved wetting and adhesion

PCL bonded to CH on both sides resulted in a more compact and uniform structure with good transparency but accelerated degradation. In contrast, PCL in the outside layers slows down degradation. The adjustable biodegradability enables tuning material production based on product requirements and environmental conditions. For instance, short-term packaging applications can incorporate faster-degrading configurations to reduce landfill accumulation and related environmental effects.

Films with CH as the outer layer exhibited a mass loss of up to 15% after 72 hours in simulated conditions, compared to 5% to 7% for films with PCL on the outside. Pure CH films degraded even faster, losing about 20% mass in the same period, while pure PCL degraded much more slowly (around 1% mass loss).

The thickness of the triple-layer films ranged from 70 to 100 µm, higher than that of the pristine CH films. The increased thickness of the film with the hydrophobic PCL layer reduces the permeability of water vapor, carbon dioxide, and oxygen, improving moisture control and food shelf life. For example, water vapor permeability in the multilayer films was reduced to 1.4 × 10⁻¹⁶ m·g·Pa⁻¹·m⁻²·s⁻¹, significantly lower than that of pure CH films (6.2 × 10⁻¹⁶ m·g·Pa⁻¹·m⁻²·s⁻¹).

Electrospun PCL fibers exhibit good ductility, lightness, and high corrosion resistance, enhancing the materials' mechanical characteristics. While medical-grade PCL offers superior performance, technical-grade PCL also yields viable and cost-effective options. Technical-grade PCL fibers tend to have more surface defects and slightly lower mechanical and barrier performance, but their cost-effectiveness and availability make them attractive for commercial applications. This flexibility in material choice could reduce production costs, making these biodegradable films more economically attractive for widespread industrial adoption.

At the molecular level, hydrogen bonds between CH’s amino or hydroxyl groups and PCL’s carbonyl group reduce stiffness and enhance the plasticity of the polymer material. Partial migratory movements of water molecules and glycerol from the CH layer toward the PCL structure also affect the mechanical features of multiple-layer films.

Thermal analysis revealed that medical-grade PCL, which is less crystalline, interacts more strongly with CH and shifts the melting temperature of CH to higher values, indicating enhanced interfacial bonding. Technical-grade PCL provided higher melting enthalpy, suggesting greater crystallinity but slightly less interaction with the CH matrix. These differences may influence both mechanical and degradation behaviours of the films.

The study findings highlight the potential of multilayered biopolymer films as eco-friendly packaging solutions for the food industry. Integrating electrospun PCL polymer fibers into CH films improves their barrier function, functional versatility, and mechanical properties. The CH/PCL/CH films showed the most preferable results, including more than double the fracture strain and tensile strength of pure CH films. They also demonstrated improvements in hydrophobicity, transparency, and gas permeability.

The performance and degradation profile of these films can be tuned by changing the grade of PCL and the arrangement of the layers, providing a customizable solution for various food packaging needs.

Journal Reference

Jakubska, J., et al. (2025). Innovative Multilayer Biodegradable Films of Chitosan and PCL Fibers for Food Packaging. Foods, 14, 2470, DOI: 10.3390/foods14142470 https://www.mdpi.com/2304-8158/14/14/247