The large variety of cell types available in ERWEKA's flow-through cell tester DFZ II allows it to be used for a variety of purposes, such as testing low-dose formulations with sustained release or poorly soluble products.

Dissolution tests can be prepared and carried out rapidly, thanks to innovations like the future-proof cell design with increased leak-tightness and the optimized tubing system with quick locks. The cell bodies can be heated separately and guarantee better cell warming. The Disso.NET 3.X software makes it simple to control all USP 4 DFZ II units via a controller.

ERWEKA USP4 Flow-Through Cell DFZ II

Video Credit: ERWEKA

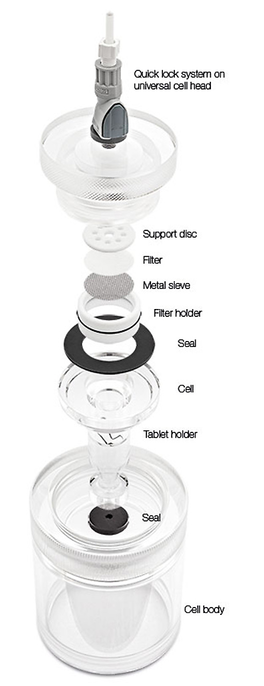

New Improved Cell Design

ERWEKA provides a range of improved-design cells for various applications to go along with the flow-through systems, including implants, suppositories, stents, and granule and powder cells in addition to normal tablet cells.

Together with the standardized flat gaskets (which consist of just three parts per cell: the connection, the head, and the heating jacket), the standardized cell head fits all available cell bodies and makes handling and installing the cells easier. Better cell heating is ensured by the optimized cell bodies with thinner cell walls.

This concept makes it easier to mount the cells on the DFZ II flow tester, which speeds up the preparation and execution of dissolution tests.

Image Credit: ERWEKA

Image Credit: ERWEKA

Flow-Through Testing Enhanced by Innovative Design

Standardized Cell Head

The new cell head fits all available cell bodies, cell assembly can be completed more quickly and at a cheaper cost (only one per system is needed). A rapid lock in the cell head also allows for faster tube attachment.

Increased Leak-Tightness

Process safety can be improved by employing flat seals with a larger sealing surface and limiting the number of seals to three pieces per cell.

Optimized Cell Bodies and Individual Cell-Heating

When the cell body is smaller, cells can be prepared more quickly and with better heating. A rotary switch can be used to individually heat each cell.

Compact and Corrosion-Resistant Housing

In addition to saving laboratory space, the cells' clear line arrangement and reduced footprint provide constant, flawless visual control over the cells. The device's tube organizer on the back keeps the cell tubes organized.

Easier Cleaning

Cleaning the water bath is made much simpler by the device's three-way water drain valve on the back. Additionally, checking the water level is made simple by the color-coded water level indication and the two PT 100 sensor apertures on the device cover.

Full Dissolution Software Solution for the Flow-Through Cell

Disso.NET USP 4

The ERWEKA Disso.NET USP 4 software is the ideal partner for all ERWEKA USP 4 systems. The software supports all USP and EP dissolution cells utilized in the systems and assumes complete control of them. Additionally, it has cells for specific uses (such as cream adapters) and visual guides for positioning formulations in the appropriate cells.

The software comes with an intuitive method editor for quick programming of dissolution methods (for optimal safety in a GMP environment). When the dissolution test is over, Disso.NET 3.X generates thorough reports (in PDF files) and can export all of the results in different formats (such as XML files).

Image Credit: ERWEKA

LMT 2 Easy Media Transfer

The compact ERWEKA LMT 2 media transfer station makes it simple to set up a closed loop for conducting long-term dissolution tests in compliance with USP 4. As a medium reservoir, the LMT 2 makes sure that the media is mixed and distributed as best it can throughout the release test.

The rotatable bottle caps (safety caps) and tube holder in the optimized tubing system make handling easier and conserve important lab space.

Image Credit: ERWEKA

Technical Data

Source:ERWEKA

| |

|

| Weight |

8 kg |

| Dimensions (H x W x D) |

290 x 540 x 220 mm |

| Voltage |

115/220/240 V; 50-60 Hz |

| Interfaces |

RS 232 (PT 100 sensors) |

| Number of cells |

7 cells in a row |

| Water bath |

6 liter volume, level indicator, emptying via 3-way valve |

| Heating |

Flow-through heater, cell warming of stations individually switchable |

| Connecting block |

Connecting block with a safety valve in each station |

| Temperature control |

- External PT100 temperature sensor

- PT100 temperature sensor in each station (optional)

|

| Test cells and inserts |

- Tablet cell 22.6 mm (standard)

- Tablet cell 12 mm

- Suppository and capsule cell

- Powder & Granulate cell (USP+EP)

- Stent cell

- Implant cell

- Gel and cream application for 22.6 mm tablet cell

- One-way adapter with 22.6 mm tablet cell

- Cleaning cell for system cleaning

- Temperature-calibration head

|

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA