This combo tester is completely automated and loaded with cutting-edge technology: Among the many cutting-edge features is a patented Oblong Navigator®, a capsule weight measuring system, and an easy-to-use touch screen with integrated MC.NET software functionality. The MultiCheck 6 has the cleanest functioning in its class and an unmatched low noise level.

ERWEKA MultiCheck 6 Tablet Hardness Tester

Video Credit: ERWEKA

Proven features have been retained: The MultiCheck 6 is a true all-arounder that is completely automated, 100% compliant with all pharmacopeias worldwide, and capable of testing up to five tablet parameters.

The Next Generation of MultiCheck

Key Features

Capsule Weight Measurement

Thanks to its empty capsule weight measuring mechanism, MultiCheck 6 can measure the weight of empty capsules and automatically subtract the weight of the empty capsule from the weight of the filled ones. The measuring process is accelerated by direct ejection right after the weight measurement.

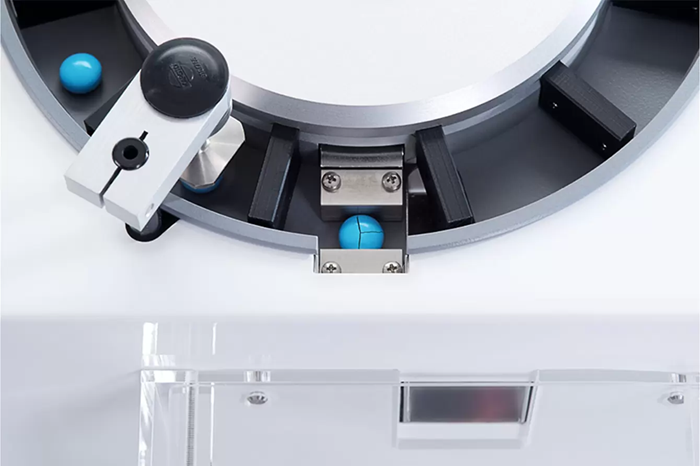

Oblong Navigator®

The innovative turntable technology makes evaluating the diameter, width, and length of irregularly shaped tablets and oblongs simple.

Touch Display

The device is simple to use due to its intuitive touch display.

Direct Measurement

Tests can be initiated rapidly, and results can be saved instantly using the direct measurement menu.

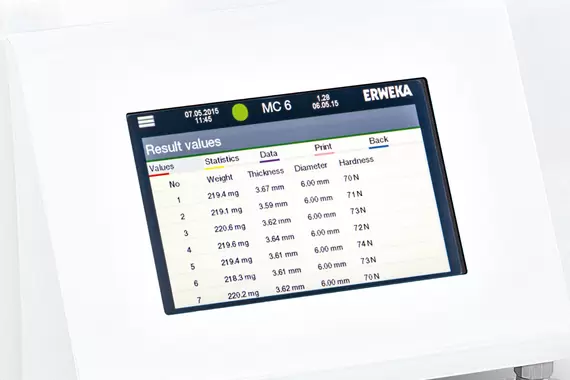

MultiCheck 6 Touch Display

Easy to Use - Extensive Features

When creating the MultiCheck 6 touch display, ERWEKA concentrated on the features that would be most helpful to the user: creating methods quickly and easily, initiating tests, and recording test results. The touch display's intuitive design makes using the available functionalities simple. Measurements can be initiated, and results are shown directly on the device. MultiCheck 6 can also be controlled via our MC.NET software via a PC.

Test Result Storage

The device stores 100 products and methods as standard. Its product memory can store up to 1 million test results, allowing for easy retrieval of past test data at any time.

The Audit Trail Light feature (which logs What, Who, and When) and comprehensive, integrated calibration functions guarantee that the user can always access accurate test findings and thorough documentation of every work step - maximum usability paired with robust functionality.

Image Credit: ERWEKA

Tablet Hardness Tester MultiCheck 6

Testing of Up To 5 Parameters for All Kinds of Tablets

- Weight

- Thickness

- Diameter / Length

- Width

- Hardness

Automatic Calibration Tool

AutoCal 2.0

The ERWEKA AutoCal 2.0 system is an automated calibration tool for the hardness testing station that does not require weights, an external PC, or software.

Calibration has never been so easy: Plug the AutoCal 2.0 USB stick into the TBH x25's USB port, then place the certified load cell into the hardness testing station.

The hardness tester's keypad and display are now used to operate the entire system (calibration and adjustment). Up to three places within the measuring range can be examined for linearity in the calibration, and the device adjusts automatically. The regular printer interface can be used to create a documentation report.

Image Credit: ERWEKA

Image Credit: ERWEKA

Tablet Hardness Tester MultiCheck 6

Technical Data

Source: ERWEKA

| |

|

| Weight |

50 kg |

| Dimensions (H x W x D) |

613 x 627 x 643 mm |

| Voltage |

100 - 240 V / 50-60 HZ |

| Interfaces |

LAN, USB A, USB B, and SD-Card slot |

| Control |

7'' touch display, resolution 800 x 400 pixels |

| Measurement range: Hardness |

3 - 500 N (±1 N) |

| Measurement range: Diameter / Length |

2 - 23 mm (± 0.05 mm) / 2 - 28 mm (± 0.05 mm) |

| Measurement range: Thickness |

2 - 10 mm (± 0.05 mm) |

| Measurement range: Weight |

20 mg - 120 g (± 0.0001 g) |

| Measurement range: Width |

2 - 15 mm (± 0.05 mm) |

| Measurement principle: Constant speed |

0.05 - 3.0 mm / sec |

| Measurement principle: Constant force |

10 - 100 N / sec |

| Compliance MC.NET |

21 CFR Part 11 |

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA

Image Credit: ERWEKA